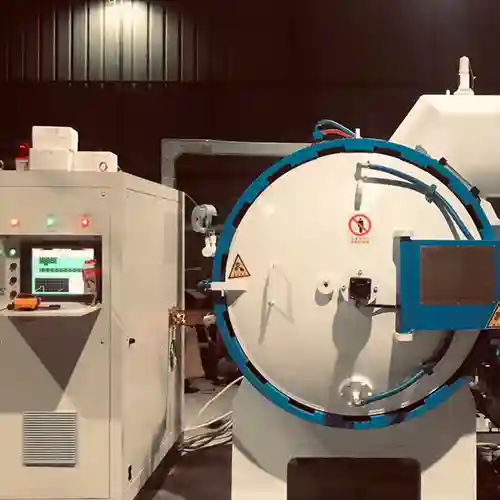

Machine Overview

The vacuum brazing furnace has the characteristics of fast installation and simple operation. To provide precise temperature control, the furnace has two (or more) temperature monitoring systems that can simultaneously monitor internal temperatures.

The control system also supports remote application operation and viewing temperature curves, which can reduce unnecessary labor costs through mobile phone operation. In addition, historical data can be saved for up to 10 years.

In addition, the vacuum brazing furnace is also equipped with an automatic (or manual) inflation device, which can be selected for fast or slow cooling as needed. This flexibility can provide more options to meet the cooling rate requirements of different products.

Overall, vacuum brazing furnaces provide users with efficient and high-quality brazing processes through simple and easy-to-use operations and precise temperature control systems. This type of equipment is widely used in various aluminum brazing industries, providing reliable technical support for product development.

Vacuum Brazing Furnace Quick Details

| No. | ITEM | DATA |

| 1 | Warranty time | 1 Year |

| 2 | Usage | Aluminum Brazing |

| 3 | Chamber size | Customised |

| 4 | Customized | 620-650℃ |

| 5 | Heating Rate | 0-20℃/min |

| 6 | Certificate | CE |

| 7 | Max temperature | 750℃ |

| 8 | country of origin | China |

Vacuum Brazing Furnace Features

- The working temperature of this vacuum brazing furnace is 620-650 ℃ (up to 750 ℃), which can meet the needs of brazing various aluminum materials.

- To achieve maximum energy efficiency, the brazing furnace uses alumina fiber ceramic insulation material with high thermal efficiency to surround the chamber, reducing energy loss and waste.

- The brazing furnace adopts a heavy-duty double-layer structure and is equipped with water cooling to ensure lower shell temperature and improve equipment safety and stability.

- The brazing furnace uses PID automatic control technology with current limited phase angle trigger resistors, such as SCR (silicon-controlled rectifier), to control precise temperature. This control method can adjust the current and phase angle of the heating elements in the brazing furnace, achieving precise temperature control.

- This brazing furnace has 51 programmable power control segments. Users can develop different power control curves according to the brazing process requirements to meet the brazing requirements of various materials and processes. This flexible control function can provide more options and optimize the brazing quality.

Cooling system

1, This vacuum brazing furnace is equipped with a water circulation system. It can effectively cool the furnace body, maintain the temperature of the furnace body within a safe range, and avoid overheating and damage.

By circulating water flow, the heat generated by the furnace body can be effectively absorbed and taken away, maintaining a stable temperature inside the furnace.

2, When it is necessary to reduce the temperature of the furnace body, this water-cooled circulation system can accelerate its operation, thereby achieving the goal of rapid cooling.

Adjusting the working parameters of the water cooling system makes it possible to improve cooling efficiency, save time, and meet process requirements.

3, Therefore, the water circulation system of the vacuum brazing furnace does not require manual intervention, and its operation and shutdown are all automatically completed by a programmable control system

WECHAT

WECHAT