Machine Overview

The automotive radiator industry uses the tube testing machine as a high-frequency welded aluminum tube pressure burst testing equipment.

During the production process of aluminum flat tubes, continuous pressure testing is required to check whether their welding meets the technical requirements.

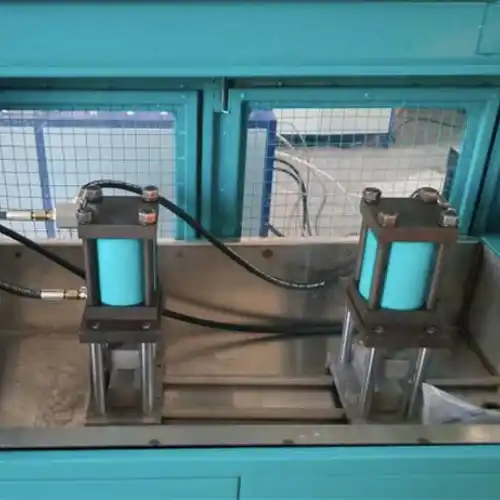

This aluminum tube tester is a multi-purpose type. Based on a pressure testing system, it can be used to test flat tubes, square tubes, round tubes, and radiators by simply replacing the fixture.

Tube testing machine technical parameters

| No. | ITEM | DATA |

| 1 | Aluminum tube | φ 16~ φ 50mm |

| 2 | Wall thickness | 0.6-2.5mm |

| 3 | Burst pressure | 50 MPa |

| 4 | Measurement accuracy | ≤ ± 0.5% |

| 5 | Testing length | 100-900mm |

| 6 | Control mode | Computer control |

| 7 | Tube long side | 30-90mm |

| 8 | Tube short side | 3-40mm |

Tube testing machine Working principle

This device mainly uses compressed air as a power source, which drives hydraulic cylinders to achieve pressure output. Its maximum pressure reaches 50Mpa,

Engineers can adjust valves to achieve precise pressure control by the input compressed air flow rate. The entire equipment has a compact structure and is easy to operate

Display the test data as a curve on the computer, allowing engineers to check pressure changes visually. The test report is output in Word format,

Aluminum tube testing machine Characteristics

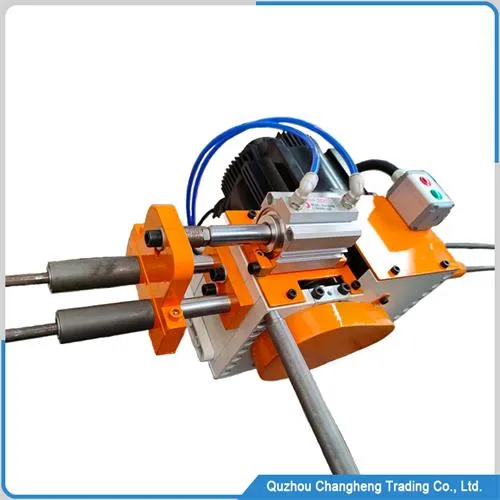

1, Pneumatic boosting design

This device does not require a hydraulic station to provide power, with a maximum pneumatic boost pressure of 50mpa, and can test any radiator pipe

2, The pipeline adopts free connection,

This structure is simple, well-designed, and easy to maintain,

3, Industrial computer control

It can connect to a printer, and every test can print a report, which is very convenient

4, Safety protection

The Tube test machine has a protective cover, which ensures safety and reliability during the aluminum tube blasting test process

5, Multiple valve control

This machine has multiple valves, and engineers can freely and accurately adjust the pressure. It can test different sizes of aluminum tubes.

WECHAT

WECHAT