Machine Overview

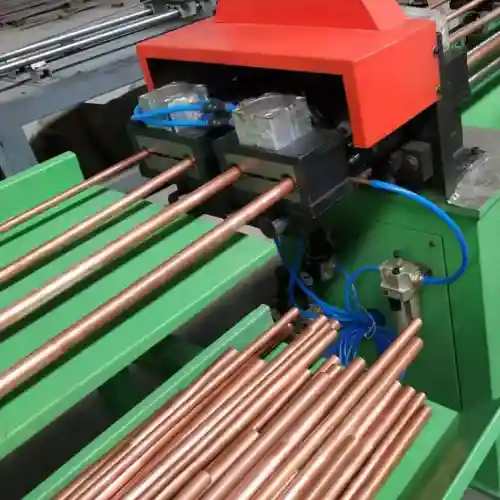

The copper tube straightening machine is a key production equipment in the HVAC industry. It is a device that accurately cuts coiled copper pipes after straightening them. This equipment uses a burr-free cutting technology, and the edge of the tube will be reduced by 0.5mm. This is to make it easier for the tube to be inserted into the hole of the fin.

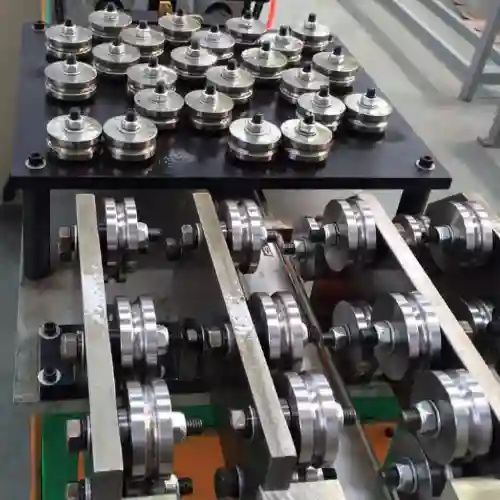

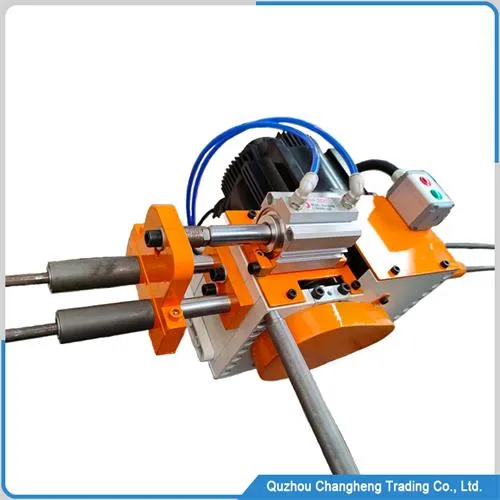

The equipment consists of a coil storage device, multiple roller straightening devices, a flywheel cutting device, a control system, etc. Among these, the flywheel cutting is one of the key parts. Inside it, 3 fast-rotating wheels cut the tube under the pressure applied by the cylinder. This cutting technology does not produce lint and does not waste raw materials.

This machine has 6 straightening and cutting workstations, and users can choose 6 different tube sizes. This means that a factory only needs one machine to meet all its production needs.

Tube straightening machine data

| No. | ITEM | DATA |

| 1 | Drive | servo motor |

| 2 | Workstation | 4-8 optional |

| 3 | Pipe diameter | 6-20mm |

| 4 | control type | touch screen |

| 5 | Pipe type | Soft state |

| 6 | Application field | Heat exchanger |

| 7 | Production type | fully automatic |

| 8 | Cutting technology | No burrs |

| 9 | Tube material | Copper and aluminium |

| 10 | Minimum length | 30mm |

| 11 | Maximum length | 6000mm |

Tube straightening machine advantage

- Multiple workstations work in coordination

Users can choose 4-10 workstation machines according to production needs and select different tube diameters for each workstation. This design of multiple workstations and multiple sizes not only improves production efficiency, but also expands the application scenarios.

- High-precision control

The machine uses a servo motor to drive the screw, which effectively controls the length of each cut tube and ensures the consistency of the size of the metal tube. The length error of each tube will not exceed 0.01mm.

- Cut metal tubes of any length

Switching the length of the tube won’t involve a complex debugging process. Engineers only need to set the length of the tube on the touchscreen. If a super-long tube is to be cut, the Tube straightening machine’s PLC will perform automatic calculations. It will make the servo motor move multiple times to calculate the tube length to meet the set size, and then proceed with the cutting.

- Noise-free production.

A servo motor drives the machine, and the straightening rollers are made with high precision. It also has high-quality bearings, so this equipment will not make any noise during operation.

- Fully automatic operation.

The machine does not require the participation of workers in the production process. After the tube cutting, the table will automatically store and organize the tube properly.

Tube straightening machine working video

The control system of tube straightening machine

- The control system of this machine uses a PLC, and the human-machine interface is a 7-inch touchscreen. The brand of this touchscreen is from Shenzhen, China. It is a screen specifically designed for industrial machines. It not only has a high-definition resolution, but also has sensitive touch control.

- The touchscreen offers two languages for users to choose from, usually Chinese and English. Of course, we can also customize languages for users, such as Russian, French, Spanish, etc.

- Other electrical components are from internationally renowned brands, such as Omron, Chint, Mitsubishi, etc. If you have a preferred brand, please let us know, and we will purchase parts from your preferred brand to install on this Tube straightening machine.

- Touch screens can complete all operations, but we still keep physical buttons. In an emergency, workers can quickly press the stop button to stop the machine, which helps ensure safety.

Other HVAC machines

Tube bending machine for heat exchangers

Machine Overview In the heat exchanger manufacturing industry, many U-shaped hairpin tubes are needed. Traditional U-tube bending machines rely on hydraulic stations for drive, which consume a lot of energy and generate a lot of noise. It isn’t easy to…

Water pressure Tube expanding machine

Machine Overview The water pressure Tube expanding machine is special equipment useing in the heat exchanger industry. It consists of a control system, a pressurization system, and special tools for pipes. The water pressure expansion machine have a 7-inch touch…

Convenient Portable tube expander

Machine contour A servo motor drives this portable tube expander, easily expanding pipes into various required sizes. Its easy-to-use touchscreen interface makes it convenient for users to operate and set up. This portable expansion machine is suitable for producing large…

FAQ

A: Both soft aluminum and copper can be straightened

A: This is a great idea; we can meet your requirements

A: No special requirements

WECHAT

WECHAT