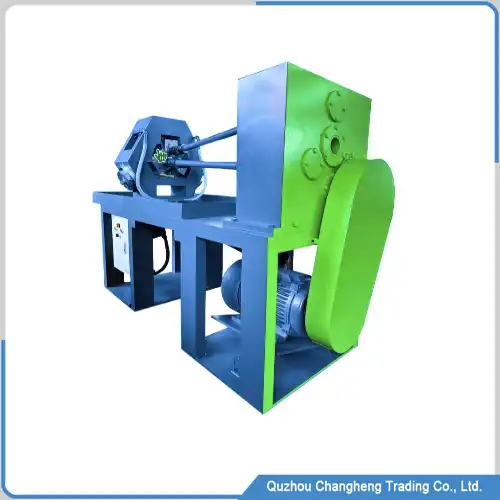

Machine Overview

The Spiral tube machine is a production equipment for squeezing metal pipes. The machine squeezes the pipes to form a spiral shape inside, allowing water to flow through the pipes and form vortices to achieve better cooling effects,

This machine has 3 sets of rollers for simultaneous extrusion production without additional cost. It can produce any type of metal pipe, such as aluminum, copper, iron, stainless steel, etc

Spiral tube machine advantage

1, Application of multi-metal pipes

This device can produce various types of metal pipes without additional costs

2, Automatic cooling device

The device is already equipped with an automatic cooling device, and the coolant can be recycled

3, Multi-size application of roller molds

A roller mold can produce various pipes with different diameters, and this flexible design can save factories a lot of costs

4, Powerful power

This machine has an 11kw motor and undergoes multiple sets of gear transmissions. Its output power is strong, allowing for high-speed production and improving production efficiency

Spiral tube machine data

| No. | ITEM | DATA |

| 1 | Appearance: | Green |

| 2 | Roller: | 3 sets |

| 3 | Tube type: | spiral shape |

| 4 | Tube Metal: | Any |

| 5 | Wall thickness: | max 2mm |

| 6 | Motor: | 11kw |

| 7 | Power supply: | 3-phase |

Production and application

The spiral tube machine adopts three sets of rollers for simultaneous and uniform extrusion molding. During the production process, it is fully automatic. Workers only need to put the metal tube into the fixture, and the machine itself will complete the rest

The two sides of the machine are designed with hollowing out, which can produce metal pipes of infinite length. Some factories produce pipes with a maximum length of 6 meters because they are too long and difficult to handle

The position of the installation roller has an adjustable screw, which can be adjusted to produce pipes of different diameters,

Please advise:

If adjusting it, the spiral tube machine three sets of rollers need to be carried out simultaneously, and the adjustment size parameters of the three sets of rollers need to be the same so that the three sets of rollers have the same extrusion force the best

spiral tube machine working video

FAQ

A: Yes, it can quickly replace molds.

A: We have fin tube machines that produce two types of metals. It is somewhat different from this machine

A: Under the correct circumstances, it will take approximately 35 days.

WECHAT

WECHAT