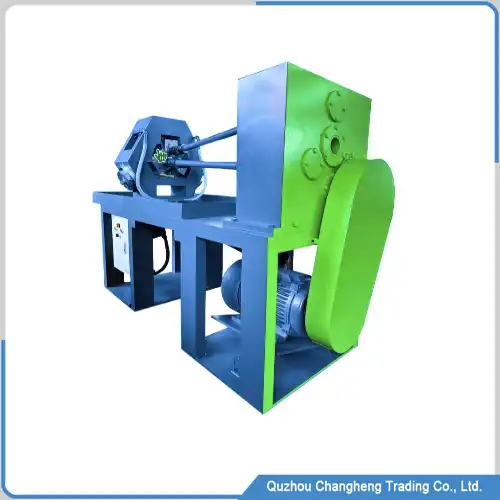

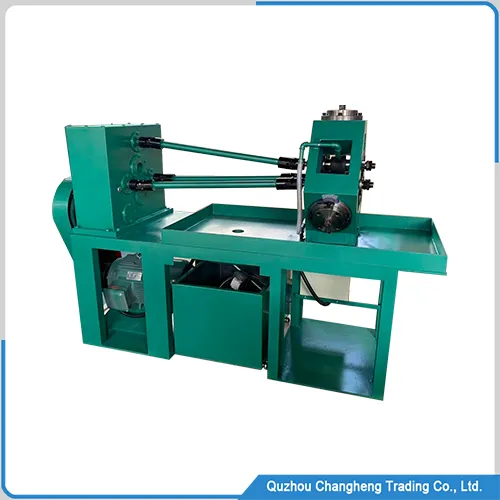

Machine Overview

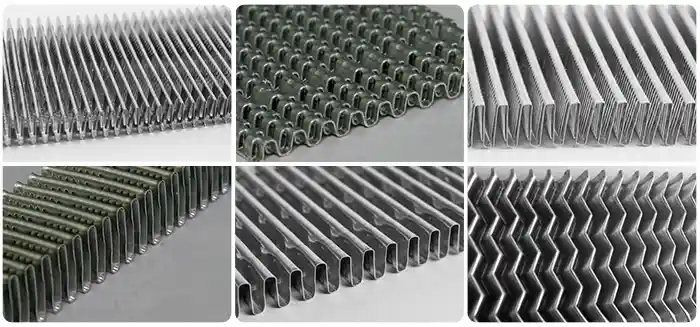

The parts produced by this serrated fin machine are used for heat exchangers and are divided into inner and outer fins. This serrated type of fin is installed inside the aluminum tube, effectively increasing the resistance of the medium flow and achieving a better cooling effect.

This machine can replace molds to produce inner and outer fins. Its flexible mold replacement design can meet users’ diverse production needs.

This machine consists of feeding, lubrication, fin manufacturing, cutting, and other parts and can achieve a fully automatic unmanned production mode.

Serrated fin machine quick details

- Fin types: serrated, wavy, straight, oblique, louvered, irregular, etc

- Fin mold: switchable

- Production mode: fully automatic

- Fin materials: aluminum, copper, stainless steel, titanium alloy

- Fin height: 1.2-40mm, customizable

- Cutting: servo control

- Lubricating oil type: volatile oil

- Machine color: Available in blue and gray

- Maximum fin width: 300mm, 450mm, 600mm, three machine options available

- Packaging: Wooden crate that meets international standards

- Delivery time: 45-50 days

- Power supply: 380V three-phase

- Voltage: 5.5kw

- Machine weight: 1.65 tons

Advantage of serrated fin machine

1, This machine can replace molds to produce various types of fins,

2, There is no need for workers to participate in the production process, which can save a lot of labor costs

3, The device is centrally operated through a touch screen, and the screen language can be set according to user needs

4, It can produce fin products made of various metal materials, such as aluminum, stainless steel, titanium alloy, as well as copper and iron

5, Equipped with a lubrication device, high-speed production protects the mold from wear and extends its service life

Serrated fin machine working video

Characteristics of cutting device

The cutting device is one of the important components of the machine, which is driven by a servo motor and can accurately control the length dimension of the fin product, effectively ensuring consistency,

This machine has an independent control system and can cut any fin type by setting parameters on the screen. If your fin width is less than 150mm, this serrated fin machine can cut two fins simultaneously.

The cutting blade is high-strength metal, with guide rails on both sides to assist in positioning. The cutting power comes from a pneumatic cylinder. If the blade edge becomes dull after long-term use, users can easily correct it with a high-precision grinder.

Other fin machines

FAQ

A: Of course, you can use any lubricant except for dense gear oil.

A: Usually 150mm and 300mm; we have two sizes for you to choose from

A: Yes, we have these services.

WECHAT

WECHAT