Product Description

The dedicated tool for the entire sawtooth fin mold plate and fin heat exchanger is made of high-hardness steel, and the key serrated parts are vacuum quenched to ensure their hardness and wear resistance.

This fin tool needs to be installed on a professional fin machine. Typically, one machine requires multiple molds to produce aluminum fins of different shapes to meet the needs of different customers.

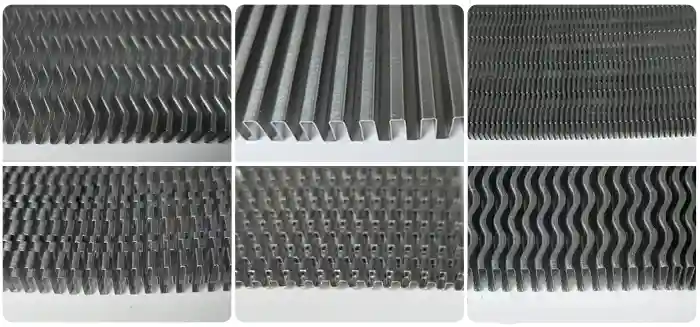

Features of sawtooth fin mold

The key components are independently designed, and when they break during use, they can be replaced at a very low cost.

Reasonable structural design significantly increases its service life

Both the top and bottom molds are equipped with multiple vertical guides and high-strength springs, which can ensure stable quality output during high-speed production

High-precision instrument manufacturing ensures that the dimensions of each component are within a reliable tolerance range

Our scope of service

- Forming mould

- Drawing dies

- Punching die

- Cutting die

- laminated evaporator Drawing die

- Industry fin heat exchanger die

- fin Serrated mold

- fin sawtooth type

- Flat-type fin mold

- Wave fin mold with holes

Sawtooth fin mold working video

Why choose our Sawtooth fin molds

We have been deeply involved in this field for many years, providing fin machines and fin molds to global users, and improving user satisfaction has always been our goal of hard work,

Over the years, our engineers have continuously explored and improved, and our fin molds maintain strict tolerance requirements, sustainable service life, and competitive prices, earning the trust of our customers.

We customize various types of fin molds for you and help you design one based on your design parameters or heat exchange efficiency.

WECHAT

WECHAT