Device outline

The Radiator fin rolling machine is an automated equipment used for producing radiator fins, which mainly consists of feeding, rolling forming, cutting, and other parts.

The feeding section is responsible for feeding the aluminum foil raw materials into the machine’s interior. It adopts an automatic feeding device, which can achieve continuous and stable feeding and improve production efficiency.

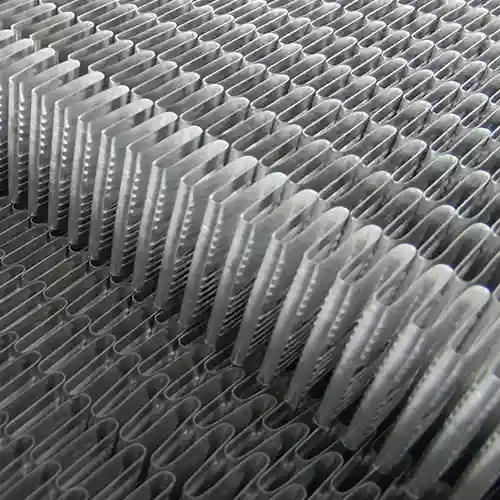

The rolling forming part is a key step in the production of radiator fins. This section rolls the material through rollers to form the desired fin louver shape.

Then cut the rolled formed radiator fins to meet the requirements of different sizes and specifications. The cutting part is controlled by a servo motor, which can achieve precise cutting, and improve production accuracy and consistency.

Radiator fin rolling machine application

The fin roller machines are mainly used for producing fins, which are important components for radiators and have excellent heat dissipation performance and durability. Therefore, the application of this machine is very extensive, including the following fields:

1, Automotive industry: Automotive radiators, condensers, evaporators

2, Generator field: The cooler in this field requires the use of this machine to produce fins.

3, In the field of household air conditioning: This type of machine is also needed for household air conditioning condensers and other equipment

4, Industrial sector: Large heat sinks, etc. in the industrial sector

Radiator fin rolling machine data

| No. | ITEM | DATA |

| 1 | max fin width | 180mm |

| 2 | max foil thickness | 0.15mm |

| 3 | max speed | 120m/min |

| 4 | Lubricating oil | volatile oil |

| 5 | Lubrication type | automatic |

| 6 | fin material | aluminum copper |

| 7 | fin height | 5-12mm |

| 8 | delivery time | 55days |

radiator fin rolling machine working video

FAQ

A: Replacing the roller mold can produce without louver fins.

A: This is a combination of rollers that can produce 2 fins of different widths.

A: We can customize the touch screen for your preferred language.

WECHAT

WECHAT