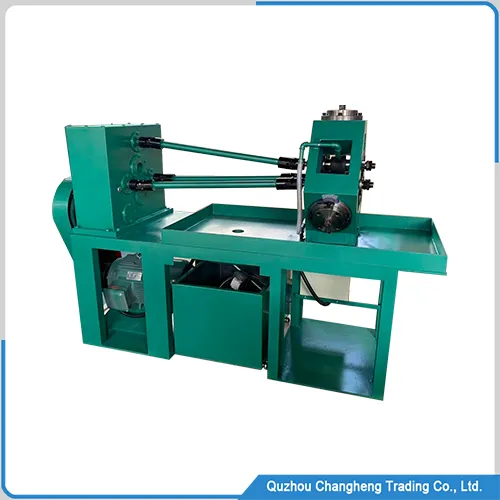

Machine Overview

The radiator fin forming machine is an efficient and high-speed specialized equipment mainly used for producing radiator fins.

This type of equipment adopts continuously variable speed technology, which can operate stably at high speeds, greatly improving production efficiency.

This device is equipped with an automatic lubrication system, which can effectively lubricate the roller mold, reduce wear, and extend the service life of the machine.

At the same time, the servo motor drives and controls the length of the fins, which can achieve precise control of the fin length, ensuring the production quality and consistency of the fins.

The 7-inch touchscreen equipped with this radiator fin forming machine provides engineers with an intuitive and convenient operating interface.

Through this screen, engineers can monitor the production process in real-time and control the length of fins according to production requirements.

This function makes the operation of fin forming equipment more flexible, meets the changes in different production needs, and improves production efficiency and quality.

At the same time, the design of the touch screen also enhances the usability of the equipment, allowing even workers without professional training to quickly get started, further reducing production costs.

Radiator fin forming machine data

| No. | ITEM | DATA |

| 1 | max speed | 120m/min |

| 2 | max cutting | 60times/min |

| 3 | raw material | aluminum copper |

| 4 | material thickness | 0.05-0.15mm |

| 5 | Delivery time | 55 days |

| 6 | Fin height | 4.5-15mm |

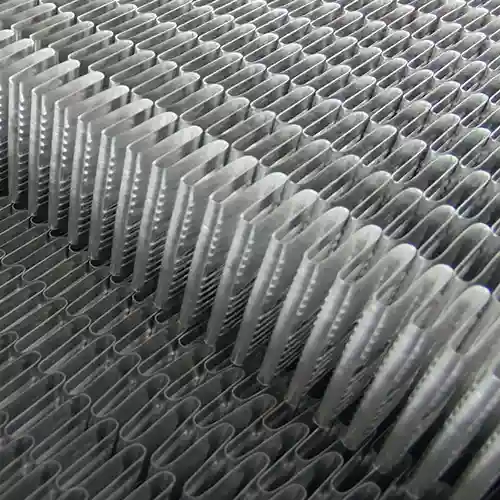

| 7 | Fin type | Louver |

| 8 | Length control | servo motor |

radiator fin forming machine application

- Automotive aluminum radiator

- Household air conditioning condenser

- Truck intercooler

- Generator cooler

- Car air conditioning condenser

- Automobile evaporator

- Computer radiator

- Air compressor radiator

Fin forming machine working video

FAQ

A: Yes, it can produce copper materials.

A: The default color is gray-white, and you can also customize its color.

A: The training for this machine takes about 2-5 days, which is enough.

WECHAT

WECHAT