Machine Overview

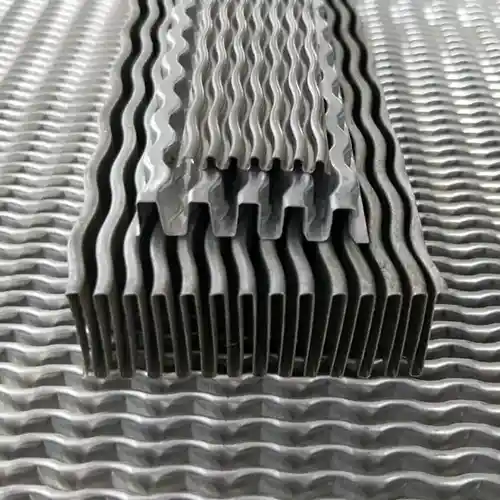

The oil cooler fin machine is an advanced continuous production heat exchanger equipment that adopts a continuous production method and can achieve fully automatic production without human supervision,

By replacing low-cost molds, various shapes of aluminum fins can be produced.

The efficiency and flexibility of this machine enable it to save a lot of time and cost in the production process. It is an essential production machine in the field of plate and bar heat exchangers

Oil cooler fin machine advantage

1, Adopting a 4-column design

This design can increase the stability of the machine, and reduce shaking and vibration during the production process, thereby improving production efficiency and product quality.

2, Servo motor control

This control system can accurately control the length of fins, ensuring that all produced aluminum fins have the same length, thereby improving product consistency and reliability.

3, Touch screen language

We can improve the user experience based on the language and interface that customers can easily understand.

4, Configure the automatic lubrication system

This lubrication system can regularly add lubricating oil to key components of the oil cooler fin machine, reducing wear and extending the service life of the machine.

5, Can produce at multiple workstations simultaneously

This multi-station design can handle multiple production stations at the same time, greatly improving production efficiency and meeting the needs of large-scale production.

6, Flexible design

This flexible design can replace different molds according to customer needs, produce various types of fins, and meet the needs of different customers.

Oil cooler fin machine data

| No. | ITEM | DATA |

| 1 | Fin height | 2.5-12 mm |

| 2 | Fin spacing | 1-10mm |

| 3 | Fin type | wave serrated straight other |

| 4 | Fastest speed | 144/minute |

| 5 | Touch screen | 7 inches |

| 6 | Language | Custom |

| 7 | Material thickness | 0.01-0.5mm |

| 8 | Fin materials | iron aluminum copper titanium stainless steel |

| 9 | max width | max-width |

WECHAT

WECHAT