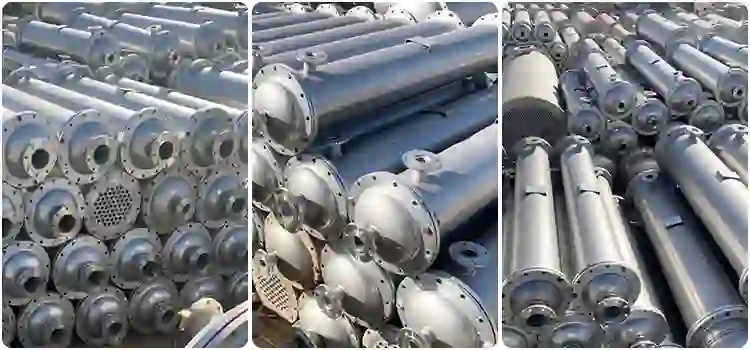

Product Overview

The shell and tube Industrial heat exchanger is a widely used type of heat exchanger in chemical and alcohol production. It comprises various components, including the shell, tube sheet, heat exchanging tubes, sealing head, baffle plates, etc. The materials for constructing the heat exchanger can vary, such as stainless steel, duplex stainless steel, titanium (Ti), and carbon steel.

In the Industrial heat exchanger process, one fluid enters from the tube connection of the sealing head, flows through the tubes, and exits from the other tube connection of the shell. Meanwhile, another fluid flows around the outside of the tubes within the shell, exchanging heat with the fluid inside the tubes through the tube walls. This arrangement allows for efficient heat transfer and effective temperature control between the two fluids.

The shell and tube Industrial heat exchanger is known for its high thermal efficiency and versatility in handling various fluid types, pressures, and temperatures. It is suitable for applications with high temperature or pressure differentials, and it can handle corrosive or fouling fluids.

Furthermore, the industrial heat exchanger’s design allows easy maintenance and cleaning. The heat-exchanging tubes can be accessed and cleaned without dismantling the entire heat exchanger. This feature contributes to the longevity and reliability of the equipment.

Overall, the shell and tube heat exchanger is crucial in chemical and alcohol production processes, enabling efficient heat transfer and temperature control. It offers durability, flexibility in material selection, and ease of maintenance, making it a popular choice for various industrial applications.

Industrial heat exchanger data

| No. | ITEM | DATA |

| 1 | Material | stainless steel carbon steel optional |

| 2 | Service life | 10-15 years |

| 3 | Internal pipe size | customized |

| 4 | water, oil, and other | water, oil, other |

| 5 | Pipe Layout: | Follow Design |

| 6 | Outer diameter: | Follow the design |

| 7 | Certificate | CE |

FAQ

A: We’re a manufacturer with more than years of professional production experience.

A: Yes, OEM is acceptable. Please provide us with the drawing or sample; we will produce it according to your requirements.

A: Neutral plywood or wooden box packaging or according to customer’s requirements.

A: We will provide you the drawing after you pay or prepay.

A: Yes, we can. Most products can be customized, including the Logo on products.

A: Normally 30 days after payment, and we promise to deliver as soon as possible.

WECHAT

WECHAT