General Overview

Heat exchanger machines are equipment used in industrial production. They consist of various devices with different functions.

These machines each complete different production tasks and ultimately produce complete heat exchangers.

In practical applications, the production of heat exchangers is a complex process that involves designing raw materials,

various production machinery, worker training, and production techniques.

This article mainly introduces a startup company and what machines are needed to produce heat exchangers.

Heat exchanger machine List

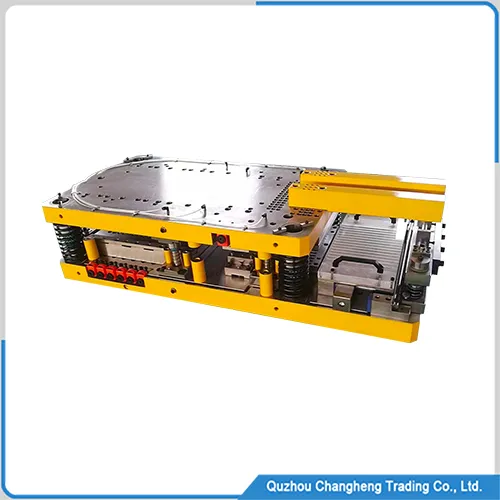

Fin-making machine and Fin mold

This equipment mainly produces aluminum fins for heat exchangers, which can be press 200-260 times per minute. Installing fin molds can achieve fully automatic high-speed production.

The heat exchanger machine consists of an automatic feeding device, lubrication device, stamping machine, finished product storage device, etc.,

The stamping machine has many sensors, and any illegal operation or malfunction will issue a warning, which is crucial for safety production.

Hairpin bending machine

The hairpin bending machine is important in producing heat exchangers. Its primary function is to bend copper pipes into a U-shape.

This machine has multiple workstations working simultaneously and can customize the size of each workstation to achieve multi-size production.

At present, this machine can achieve fully automatic production. Please check the video for more details.

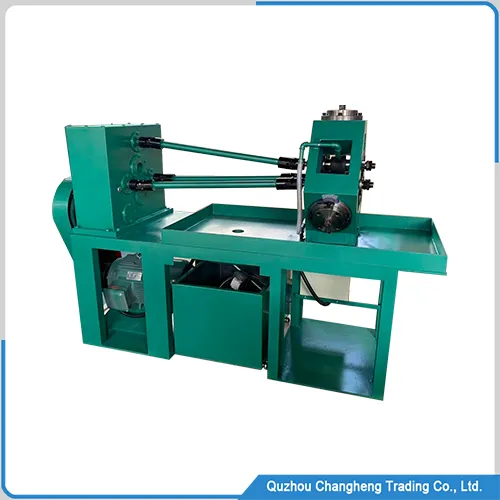

Tube cutting machine

This linear coil tube cutting machine consists of multiple workstations, each of which can independently complete straightening and cutting work.

The heat exchanger machine has a servo motor to control the length of the tubes,

and engineers can freely set the length.

Using a roller to rotate and squeeze for cutting, there will be no burrs making.

Heat exchanger machine technical service

Technology is a crucial factor in the production process of heat exchangers,

as it determines the final product quality and plays a critical role in the factory’s future development.

So whether it’s the selection of materials, the operation of production equipment, or the design of products, all require 100% effort.

It is best to choose a strong supplier for the new heat exchanger factory who can provide a one-stop purchase of this equipment and a unified after-sales service supplier. This is a very good idea.

Heat exchanger machine quality control

In the production process, every production detail is crucial to the quality of the heat exchanger. Such as the selection of raw materials, the operation of workers, etc.,

The most crucial aspect is the coordination of various dimensions. Assuming the gap between the fin hole and the tube is too large, the tube expansion cannot effectively fix the fin. If the hole size is too small, it will be difficult to insert the hairpin tube.

So, the new heat exchanger factory must find an experienced supplier to solve the machine problems in the early stages of the factory

We have extensive experience in this field, and if you are looking for a solution to produce heat exchangers, we can provide a one-stop service.

WECHAT

WECHAT