Machine Overview

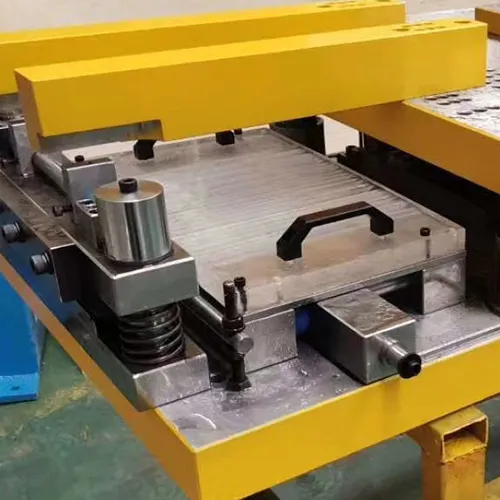

The high-speed heat exchanger fin production line is equipment based on special cast iron alloy manufacturing, which has high strength impact resistance and can maintain stable operating accuracy during the stamping process.

This production line’s slider adopts a long guide rail design and is equipped with a slider balance device, ensuring its accuracy and stability of operation.

To improve the equipment’s service life and performance, all anti-wear components of the high-speed heat exchanger fin production line need an electronic timing automatic lubrication system. If the lubricating oil is insufficient, the equipment will automatically stop running to ensure the machine operates safely.

Meanwhile, the advanced and concise control system ensures the slider’s accurate operation and stopping, meeting the requirements of high-precision component production. In addition,

The fin production line can also adapt to various automated production needs, improving production efficiency and reducing costs.

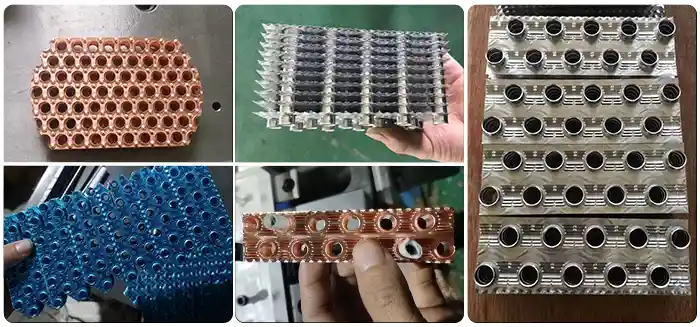

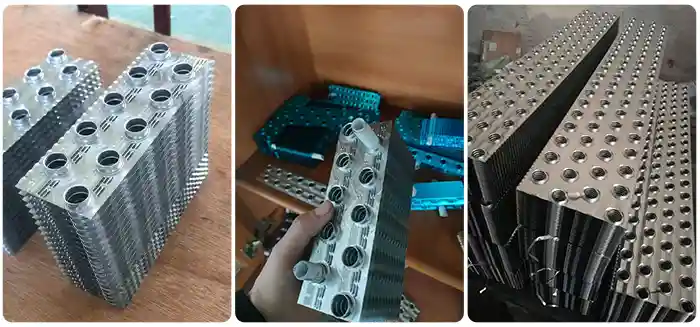

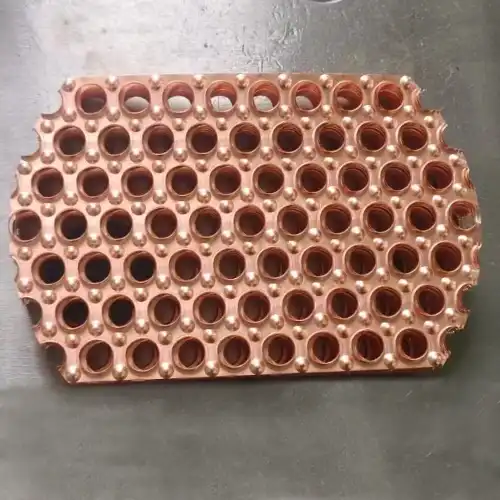

The high-speed heat exchanger fin stamping line is widely used to produce small precision parts for precision electronics, communication, computers, household appliances, automotive components, motors, and rotors.

These industries have high product accuracy, stability, and reliability requirements, and high-speed heat exchanger fin production lines can meet these needs.

Using this production line can significantly improve product quality, drive industrial development, and enhance your factory’s overall competitiveness.

Fin production line Technical data

| No. | ITEM | DATA |

| 1 | Size of Table | 80×58×10cm |

| 2 | Die Height | 200~270mm |

| 3 | Capacity | 450 KN |

| 4 | Slide of Stroke | 40MM |

| 5 | Stroke | 150~250 S. P. M |

| 6 | Main Motor Power | 5.5kw |

| 7 | Overall Dimensions | 650×250×233cm |

| 8 | Sucking Length | 1000mm |

| 9 | Die Height Adjustment: | Motorised |

| 10 | Overload Protect Type: | Hydraulic |

| 11 | Width of Material | 300mm |

| 12 | Signal Output: | Rotary Encoder |

| 13 | Angle Display: | Pilot Pin & Digital Mode |

| 14 | Crank Bearing Way | Roller Bearing |

Fin production line working video

FAQ

A: These machines are packing in wooden cases. We pack them lying down to ensure smooth loading into containers.

A: The punching force of this machine is 45 tons, and the production speed is 260 times per minute.

A: We purchase stamping machines and provide molds; one-stop purchasing can save you a lot of time.

WECHAT

WECHAT