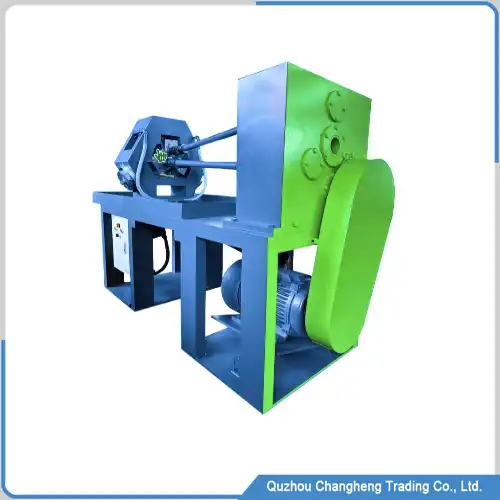

Machine Overview

A heat exchanger fin machine, also known as a heat exchanger fin high-speed press, is specialized equipment used for producing fins in heat exchangers.

This machine processes metal materials (usually aluminum or copper) into the desired shape through high-speed pressing and then bends these foils into specifically shaped fins to increase the heat exchanger’s surface area and improve its heat transfer efficiency.

Components of heat exchanger fin machine

1, Raw material uncoiler:

This is the starting point of the production line, used to unfold large coils of metal materials (such as aluminum strips) into the required width and tension strip material for subsequent processing.

2, Automatic lubrication oil tank:

During the metal stamping process, the lubrication oil tank provides the necessary lubricating oil to reduce friction between the mold and metal materials, improve stamping quality, and extend the life of the mold.

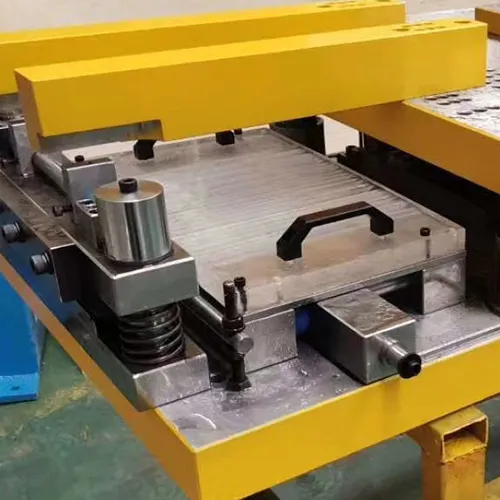

3, Stamping machine:

This is the core part of the heat exchanger fin machine, which presses lubricated metal materials into fins of specific shapes and sizes under the action of molds.

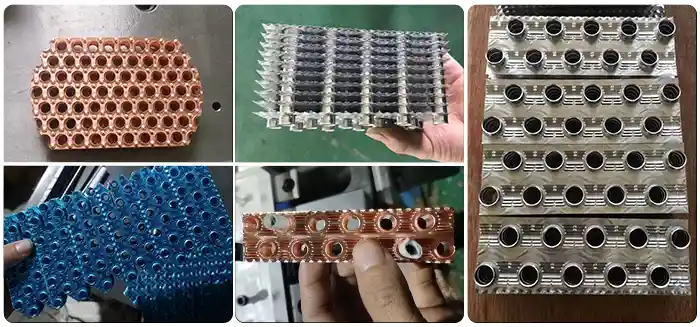

4, Fin mold:

The mold is an essential component of stamping machines, and its design directly determines the fins’ shape, size, and accuracy. Molds are usually making of high-strength materials to withstand high pressure during stamping.

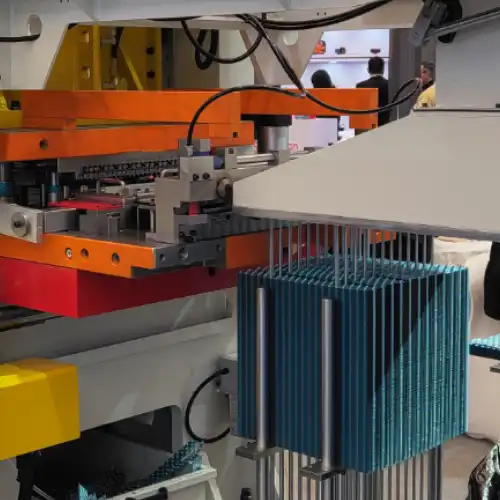

5, Fin vacuum collection device:

Stamped fins usually need to be quickly and neatly collected and placed in the designated position to avoid damaging the finished product or causing confusion.

This heat exchanger fin production line, through automation control, can continuously produce a large number of standardized and high-quality heat exchanger fins, which are widely uses in the manufacturing of various heat exchangers.

Heat exchanger fin machine Data

| No. | ITEM | DATA |

| 1 | Stamping force: | 45 tons 63 tons |

| 2 | machine Type: | C, B, H, Type optional |

| 3 | Fastest speed: | 280 beats per minute |

| 4 | Production type: | automatic |

| 5 | Mold size: | customized |

| 6 | Control type: | PLC |

| 7 | Touch screen: | Yes |

WECHAT

WECHAT