Machine Overview

This fully automatic Hairpin bender machine can bend 6 copper tubes at once. It consists of coil straightening, chip-free cutting, hair clip tube bending, and automatic material return.

The bending device of this machine is a servo motor that can set the dwell time for bending to ensure that both sides of the hair are parallel.

The user can customize the length of the hair clip tube, but the maximum length cannot exceed 2.8 meters. It has a tool for quickly switching sizes, and switching between the two sizes only takes 1 minute

Hairpin Bender Machine Technical Parameter

| No. | ITEM | DATA |

| 1 | Production type: | Automatic |

| 2 | Tube type: | hairpin tube |

| 3 | Tube materials: | copper aluminum |

| 4 | Application field: | Heat exchanger |

| 5 | Equipment model: | CH-WG008 |

| 6 | Workstation: | CHINA |

| 7 | workstation: | 6-8 pcs |

Hairpin Bender Machine Structure

This machine combines various devices with different functions to achieve automated production. Next, I will tell you their functions.

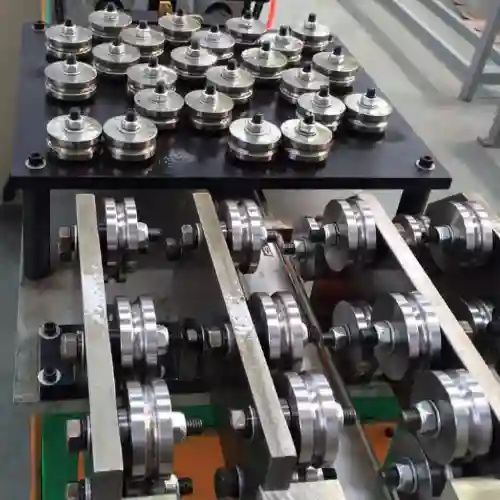

Copper tube straightening device

The copper tube is placed on the feeding device and discharged smoothly. The coil copper tube is initially straightened by passing through a curved plastic channel and then fully straightened by multiple rollers.

A cylinder clamping tool is uses to fix the copper tube, and a servo motor drives the screw to move the tool forward. The roller rotates freely to straighten the copper tube,

The servo motor will precisely control the distance of movement. If the size of one movement is insufficient, the servo motor will move multiple times to ensure that the size meets the requirements.

Chipless cutting device

The cutting of copper pipes adopts chip-free cutting technology, which is a set of circular blades that are Rotation and compression to cut without affecting the diameter of the pipe and without any burrs.

This hairpin bender machine has multiple cutting devices, all working independently without interference during the cutting process.

Automatic bending device

The bending device is located in the middle of the machine, which bends the copper tube from bottom to top to form a hairpin shape. Multiple workstations work simultaneously to ensure efficient output,

PLC controls the length of the hair clip tube, and the servo motor is responsible for driving the bending action, completing the bending and forming in one go.

Unloading device

When it is complete with bending the hair clip tube, the unloading device automatically runs, pushing the hair clip tube out of the machine and freely falling into the tray.

The power of the unloading device also comes from the servo motor drive, and its entire unloading process is very linear.

Hairpin bender machine working video

Application of hairpin tube

- Household air conditioning condenser

- Refrigerated truck evaporator

- Car heater

- Industrial air conditioning heat exchanger

- Wind turbine evaporator

- Ship heat exchanger

- Family heating

- Gas water heater

Hairpin bender machine advanced function

- Multi sized applications

This machine is a fully automatic production system with high production efficiency. For some medium-sized heat exchanger factories, it may not require fast production efficiency,

We can set different copper pipe sizes for 6 workstations, such as 7mm, 9.52mm, 15.87mm, etc. This design can meet the needs of most factories and reduce unnecessary capital investment.

- Automatic lubricating oil

During the production process of hair clip tubes, U-shaped tools require lubrication to ensure that the copper tubes are not damaged during bending,

This machine has an automatic lubrication device, which indirectly sprays lubricating oil, saving lubricating oil while ensuring smooth quality output of the hairpin tube.

Hairpin bender machine control system

The control system of this machine has a 7-inch touch screen for human-machine interaction, and all parameter settings and production data are displayed on the touch screen. Engineers can set necessary technical parameters and output through the touchscreen.

Of course, we also retained button switches for emergency operation and emergency stop, and infrared safety measures were installed on both sides of the equipment,

When other workers pass through the machine’s production area, the equipment will automatically stop, protecting workers from any harm.

The other control system components are sourced from internationally renowned brands to ensure the machine’s longevity.

Support and Services

We offer a 12-month warranty policy for this hair clip bending machine. During this period, regardless of malfunctions, we will provide free repair services as long as it is not vandalism.

We will provide spare parts for the machine delivery time, such as button switches, bearings, and parts prone to fatigue damage, to ensure that users can use the machine for 3-5 years.

This machine has two parts for easier transportation: Installation and Commissioning upon arrival at the user’s factory. This task is easy, and you can easily install it by reading the instructions. Of course, we can also provide installation and training services,

If you have special requirements for the appearance and color of the machine, we can meet them.

Summarize of hairpin bender machine

This machine is important in the heat exchanger industry. It not only realizes a fully automated production mode but also can independently produce multiple sizes to meet the needs of heat exchanger factories of different scales.

This machine has advanced control methods and the feature of quickly switching sizes, which modern heat exchanger factories highly favor.

If you are looking for a fully automatic hairpin bender machine, then our equipment is a great choice,

WECHAT

WECHAT