The progressive die (aluminum foil continuous die) comprises multiple stations. Each station completes different processing in sequence and a series of different stamping processing in one press stroke.

After a stroke is completed, the punch feeder moves the material forward according to a fixed step so that multiple processes can be completed on a pair of molds, generally including punching, blanking, bending, trimming, stretching, etc.

1. aluminum foil Progressive die is a multi-task sequential die. In one die, it can include multiple processes such as blanking, bending, forming, and stretching, with high productivity;

2. Safe operation of progressive die;

3. Easy automation;

4. A high-speed punch can produce it;

5. It can reduce the area of the punch press and site and reduce the transportation of semi-finished products and the occupation of the warehouse;

6. Parts with extremely high size requirements should not be produced by progressive die

Compound die refers to a die structure in which the punch completes multiple processes, such as blanking and punching, in one stroke

Compared with other cold stamping die structures, it has the following advantages:

① The workpiece has good coaxiality, flat surface, and high dimensional accuracy;

② It has high production efficiency and is not limited by the accuracy of the overall dimension of the strip. Sometimes, the waste corner material can also be used for reproduction.

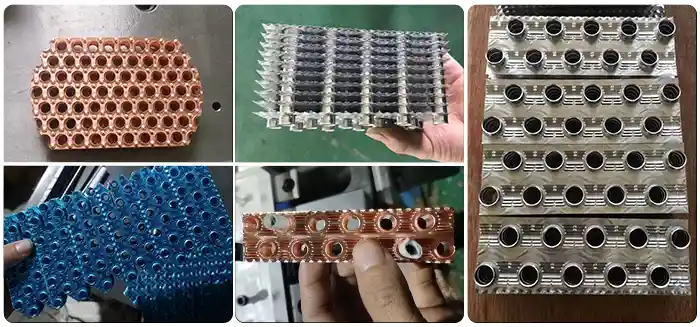

Structural features of aluminum foil progressive die:

1. The die is composed of an upper die, a lower die, and a die sleeve and is guided by a guide column;

2. The upper die is provided with an upper die fixing plate, which is supplied with a punch and connected with the upper die by screws;

3. Two semi-conical female dies are installed in the female die sleeve with conical holes, a cavity hole is opened in the middle, and the two semi-circular female dies are positioned with two locating pins;

4. The lower die is composed of a lower die fixing plate equipped with a core and another core;

5. The unloading part comprises an ejector rod and an ejector rod base plate. After the parts and products are formed, pry the upper die with a special unloading die, then push the two semi-conical concave dies out of the die with an ejector rod so that the progressive die can be separated to take out the products.

Forming process of aluminum foil progressive die:

1. In the preparation stage, after weighing the plastic powder, pour it into the feeding room and heat it to plastic. In the pressure stage, when the pressing column moves downward on the workbench of the hydraulic press, it enters the feeding room to put pressure on the molten plastic, shoots into the mold cavity at high speed through the mold pouring system, and ensures heat preservation and hardening for a certain time.

2. In the unloading stage, after opening the mold, use the special unloading mechanism to eject the plastic parts, clean the mold cavity, feeding chamber, and sprue, and prepare for the next extrusion stroke.

What is multi station progressive die?

A multi-station progressive die is a kind of cold stamping die. It is the stamping process of parts processed according to the needs in a pair of dies. It is divided into several equal distance stations. A certain stamping process is set on each station to complete a part of the stamping work of parts.

Generally speaking, multi station progressive die can continuously complete blanking, bending, deep drawing, and other processes. Therefore, no matter how complex the shape of the stamping part is and how many stamping processes are involved, it can be completed with a pair of multi station continuous dies.

Advantages of multi station continuous die

1. The heat exchanger progressive die is a multi-process die. In one die, it can include multiple processes such as blanking, bending, forming, and deep drawing. It has higher labor productivity than composite die and can also produce quite complex stamping parts;

2. The operation of the Heat exchanger progressive die is safe because people do not enter the dangerous area;

3. The multi-station progressive die is easy to be automated, that is, it is easy to realize automatic feeding, automatic output, and automatic lamination;

4. Heat exchanger progressive die can be produced by high-speed press, because workpiece and leftover can leak directly;

5. Using a Heat exchanger progressive die can reduce the pressure and the transportation of semi-finished products. The workshop area and warehouse area can be greatly reduced.

WECHAT

WECHAT