Machine Overview

The flat fin machine is an efficient heat exchanger production equipment with a four-axis design. It converts electrical energy into kinetic energy through a motor-driven cam, thereby achieving the movement of the up and down pistons.

This design enables the fin machine to provide stable and powerful power, enabling high-speed production.

This flat Fin machine comprises an aluminum foil feeder, a four-axis continuous pressing machine, an automatic lubrication device, and a servo motor-driven cutting machine, with a fully automatic unmanned production capacity.

The advantages of flat fin machine

1. Compact structure:

The design structure of the fin machine is relatively compact, with a relatively small footprint.

2. High production efficiency:

It has a high operating efficiency, with a maximum speed of 144 consecutive presses per minute.

3. Low noise:

Compared to other types of fin machines, this machine has a lower operating noise.

4. Easy maintenance:

The flat fin machine already has an automatic lubrication system, which does not require frequent maintenance and repair.

5. Flexible mold replacement:

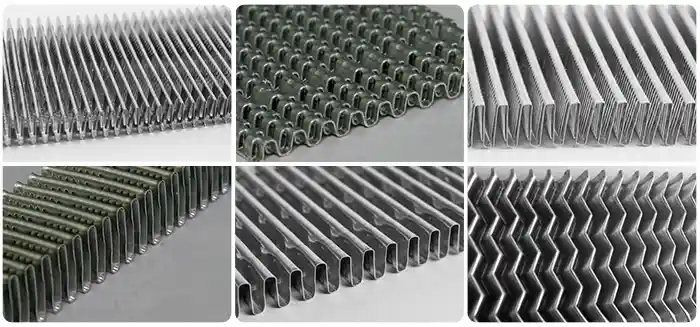

It can replace molds at a low cost and produce fins of various shapes

6. Intelligent control system:

With a 7-inch touch screen that allows users to preset production volume. After meeting production requirements, the machine will automatically stop

Flat Fin Machine data

| No. | ITEM | DATA |

| 1 | Fin spacing | 1-10mm |

| 2 | Fin shape | Wave Serrated Straight |

| 3 | Fin height | 1-12mm |

| 4 | Material thickness | 0.06-0.5mm |

| 5 | Production speed | 144 times/min |

| 6 | Fin length | Freely controlled |

| 7 | Fin materials | Iron, copper Aluminum Stainless steel Titanium |

Machine Cut-off device

The cutting device of this flat fin machine is driven by a servo motor, allowing users to easily control the length of the fins through a touch screen,

The rotation of servo motors can accurately control the length of each fin, ensuring its height consistency,

Users can preset the output of fins to operate the machine with unmanned production. When the production of the machine meets the set requirements, it will automatically stop and issue an alarm.

This intelligent control method can meet the production needs of large companies.

Flat Fin Machine working video

Support and Services

Replacing the molds of this machine requires special tools. The impact wrench manufacturer in China have made high-quality tools for us. We will provide free tools for each fin machine.

We offer a 12-month warranty for this fin machine, and during this period, we will provide free technical support if the device malfunctions.

This machine can produce various fins, providing heat transfer efficiencies and application scenarios for heat exchangers. To meet the diverse needs of our customers, we can design various fin shapes for them, manufacture molds, and produce samples.

When you purchase our Flat Fin machines, we will provide a long-term supply of parts and molds to ensure your efficient production. At the same time, we can train your engineers for free so that your factory can produce in an orderly and stable manner.

WECHAT

WECHAT