Machine Outline

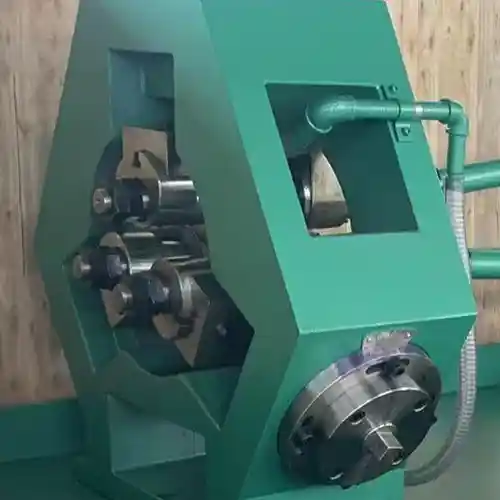

This Finning Tube Machine is used to produce circular fin tubes, with a reasonable structural design, strong extrusion ability, and simple control, which brings great convenience to the entire fin tube production process.

The main driver of this machine is an 11kw motor, which provides strong power for the entire production process. The motor drives three sets of rollers through gear conversion. These rollers squeeze the aluminum tube at a certain speed and force. This process is a crucial step in forming a thin fin tube, ensuring its shape and quality.

This type of Finning Tube Machine not only improves production efficiency but also ensures product quality. Due to its precise design and efficient operation, it has become an important tool for producing circular fin tubes.

Overall, this machine for producing circular finned tubes has become an essential equipment in the production and manufacturing of heat exchangers due to its advanced rolling technology and excellent performance.

Finning Tube Machine Advantage

- Simple control: The device only has 3 control buttons, and each operator only needs simple training to easily use this machine

- 2. Automatic cooling: This finning tube machine generates a large amount of heat during the extrusion production process. It is already equipped with coolant cooling roller blades, and this process is completed automatically by the machine

- Size customization, continuously improved by engineers, only requires cheap replacement of the roller mold. It can produce various sizes of air pipes, which saves the manufacturer’s boss money

- Silent production. The finning tube machine is designed reasonably, and three sets of rollers are squeezed simultaneously during the production process, effectively avoiding the overload operation of the machine. Therefore, the noise level of the entire production factory machine is very low

Technical Parameters

| ITEM | DATA |

| Inner tube material | iron stainless steel copper |

| outer tube material | aluminum copper |

| Inner tube diameter | 12-50mm |

| Outer pipe diameter | 13-55mm |

| Maximum length | 6 meters |

| Delivery time | 35 days |

| Power supply | Follow your factory |

| Power | 11/22kw |

| Packaging | Wooden box |

Finning Tube Machine video

FAQ

A: The default color of this machine is green, you can choose the color you like.

A: It takes about 0.5-1 hour for skilled workers to replace the mold of this machine.

A: We provide all services, but this machine is very simple and you can easily install it according to our manual.

WECHAT

WECHAT