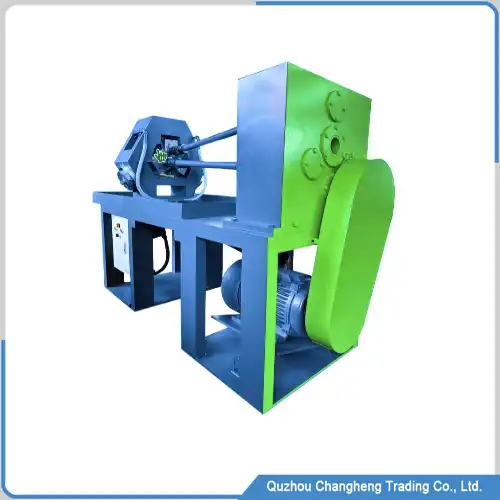

Machine Overview

The fin tube rolling machine adopts a design of three sets of symmetrically arranged rollers, which are driven by a single motor to extrude the aluminum tubes

During the extrusion process, the aluminum tube is placed between the rollers, and as the rollers rotate and compress, the aluminum tube gradually deforms and forms a threaded fin tube.

This design enables the machine to efficiently complete the production of fin tubes while maintaining ease of operation and continuity of production.

By precisely controlling the speed and pressure of the rollers, it is possible to ensure that the size and shape of the fin tube meet the predetermined standards. And for good consistency.

Fin tube rolling machine data

| No. | ITEM | DATA |

| 1 | Inner tube material | Any metal |

| 2 | Outer tube material | copper aluminum |

| 3 | Fin thickness | 0.1-0.8mm |

| 4 | Fin pitch | 2-10mm |

| 5 | Fin shape | threaded |

| 6 | Maximum length | 20 meters |

| 7 | Maximum diameter | 76mm |

| 8 | Production speed | 140 rpm/min |

| 9 | Motor power | 11kw |

| 10 | Equipment weight | 1.46 tons |

| 11 | Packaging size | 224*85*155cm |

Fin tube rolling machine advantage

1, Simple control system:

makes it easy for operators to understand and control various functions of the machine, reducing operational complexity and training costs.

2, Automatic cooling circulation system:

ensures effective temperature control of aluminum tubes during extrusion, prevents product quality from being affected by overheating, and improves production efficiency.

3, Three sets of roller design:

The symmetrical arrangement and smooth movement of the rollers ensure the uniformity and stability of the aluminum tube extrusion process, reducing the possibility of product deformation and defects.

4, Flexible design of replaceable molds:

Users can quickly replace molds according to different production needs, increasing the applicability of the machine and the diversity of production.

fin tube rolling machine working video

FAQ

A: It is a famous brand from China, and if not artificially damaged, it can be used for a long time.

A: Yes, it is packaged in wooden crates, which have undergone high-temperature fumigation and comply with international logistics standards.

A: Just use regular coolant.

WECHAT

WECHAT