Machine Overview

This fin press machine is a specialized equipment for high-speed stamping processing, which is usually used in manufacturing industries such as automobiles, household appliances, and hardware products.

This type of machine has the characteristics of high speed and precision and can achieve continuous and automated production methods, improving production efficiency and product quality.

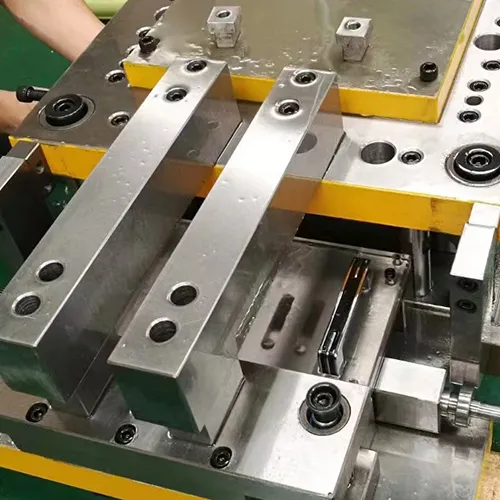

The fin press machine is equipped with advanced equipment such as aluminum foil unwinding equipment, a lubricating oil device, and an automatic feeding device to form a fully automatic production line,

This production line is usually used in conjunction with continuous fin molds, and each press can produce a complete fin, greatly improving production efficiency

The fin press machine data

| No. | ITEM | DATA |

| 1 | machine type | C type B type H type |

| 2 | Pressing force | 45T 63T 80T |

| 3 | Delivery time | 55 days |

| 4 | Machine part | feeder oil tank press machine vacuum storage |

| 5 | Control system | PLC |

| 6 | Interaction mode | touch screen |

| 7 | Crank Bearing Way | Roller Bearing |

| 8 | Signal Output | Rotary Encoder |

fin press machine Working principle

1, The aluminum foil is sent out on the unwinding machine, presenting a flat state, and preparing for subsequent pressing work.

2, The aluminum foil is automatically lubricated through an oil groove,

ensuring that friction and damage are reduced during the pressing process,

while also helping to improve the pressing efficiency.

3, The aluminum foil is fed into the mold for multiple press forming, and the fin press machine can produce a complete aluminum fin with each press.

This process fully utilizes the structure and design of the mold, allowing the aluminum foil to form quickly in a short period and improving production efficiency.

4, The aluminum fin that has been pressed is automatically cut according to the set length,

which ensures the accuracy of the length of the aluminum fin and improves production efficiency and quality.

5, The vacuum storage machine organizes all aluminum fins, ensuring consistency in aluminum fin production and reducing manual storage intervention and damage

Fin press machine working video

summarize

Overall, this aluminum fin press machine and finishing process is highly efficient and precise,

from the delivery of aluminum foil to forming, cutting, and storage, each step is carefully designed and optimized to ensure the quality and consistency of the final product.

This process not only improves production efficiency and reduces production costs, but also gains more market competitiveness for the enterprise.

FAQ

A: Usually, we customize machines and fin molds based on your fin design.

A: Of course, it can not only produce stainless steel, but also raw materials such as aluminum and copper.

A: This is a very common volatile lubricating oil

WECHAT

WECHAT