Machine Overview

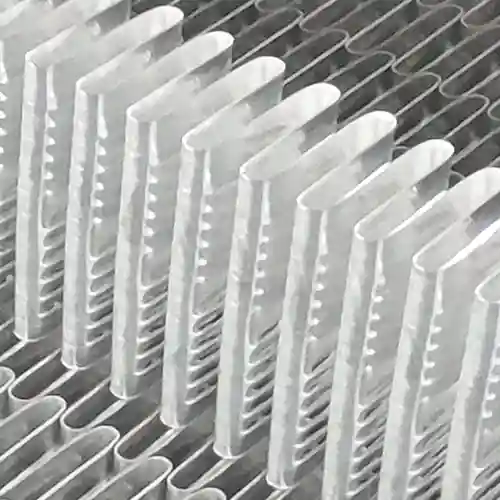

The fin mill machine are used to produce louver fins for aluminum radiators. The entire drive of this machine comes from servo motors, and it can produce up to 260 meters per minute at its fastest speed. It is at a leading level in the aluminum radiator manufacturing industry.

In addition, the lubricating oil tank of the finned rolling mill is installed on the left side of the machine and equipped with a recycling device, which not only makes adding lubricating oil more convenient but also saves costs,

The top of the machine is equipped with an air purification device to clean the lubricating oil atomized during the production process, ensuring clear air in the production workshop

The fin roller mold adopts a modular design, which can replace the mold in a short time, effectively improving production efficiency and flexibility.

Fin mill machine features

High-speed production

This machine can quickly produce fins, with a maximum speed of 260 meters per minute, meeting the needs of efficient production.

Roller mold combination design

The roller mold of the machine adopts a multi-size combination design method, which can produce various fins of different widths.

Servo control cutting

The machine adopts a servo control system for cutting operation, which can ensure the accuracy and quality of cutting.

Can produce any length

This Fin mill machine can be set through the touch screen to produce fins of any length, with high production flexibility.

Fin mill machine data

Application of machine

Because the production speed of this Fin mill machine is very fast, it accurately control of cutting, maintains high consistency in the length of each fin, and many other advantages, many industrial fields choose this fin machine as a key equipment

This fin machine has many applications in the following fields

- Car radiator,

- Car air conditioning heater

- Car and truck condensers

- Automobile air conditioning evaporator

- Generator radiator

- Air compressor heat exchanger

- Train engine radiator

- Plate and bar heat exchangers in the industrial sector

You can check these other fin machines

FAQ

A: This fin mill machine has 4 servo motors and 2 ordinary motors.

A: The cutting blade material of this machine is SK11.

A: Yes, it can produce aluminum fins for truck intercoolers.

WECHAT

WECHAT