Machine Summarize

Fin machines are important equipment in modern industrial manufacturing, especially in industries such as automobiles, home appliances, and ships, playing an important role.

There are various types of fin equipment, including extrusion, rolling, and stamping machines, each optimized for specific production needs.

With the development of technology, modern fin machinery often integrates automation control systems, which can achieve efficient and high-precision production,

This article mainly introduces the types and working types of fin equipment. If you are looking for these machines, reading this article may be helpful.

Machine list

Serrated fin machine | wave fin machine

Machine Overview The parts produced by this serrated fin machine are used for heat exchangers and are divided into inner and outer fins. This serrated…

Condenser Fin Machine Supplier From China

Machine Overview The condenser fin machine adopts a roller production method, which can produce the louver shaped fins required for microchannel condensers with extremely high…

Copper fin tube machine

Machine Overview The Copper fin tube machine is an efficient manufacturing equipment that can produce finned tubes of various metal materials, including carbon steel, stainless…

Fin die of heat exchanger supplier in China

Fin mold supplier outline We are a top fin die supplier from China, and our engineers have an average working age of over 16 years….

Fin tube machine | finning machine manufacturer

Product Description The metal fin tube machine is an upgraded third-generation equipment that can roll single and bimetal finned tubes made of steel, steel aluminum,…

Fin making machine of plate and bar heat exchanger

fin mill machines Machine outline The industrial cooling system oil cooler fin making machine, as the core equipment for processing industrial cooling systems such as…

Fin stamping machine of condenser and heat exchanger

Machine outline This high-speed fin stamping machine is an ideal fin production equipment, widely used in the automotive, household appliances, and industrial heat exchanger industries,…

Fin roller machine of radiator and condenser

Machine Outline The radiator fin roller machine is the core equipment for processing condensers, radiators, and intercoolers. Its total power is 3.5kw, demonstrating strong power….

Classification of Fin Machines

Roller type

This type of equipment is produced by rollers, mainly for automotive radiators and condensers.

Press type

Pressure-type devices are mainly used in household air conditioners and industrial heat exchangers.

Extruded type

This equipment is mainly used to extrude fins onto pipes and is widely used in the petroleum industry.

Vibrate type

This device produces disc and bar heat exchangers, which are used in engineering and machine

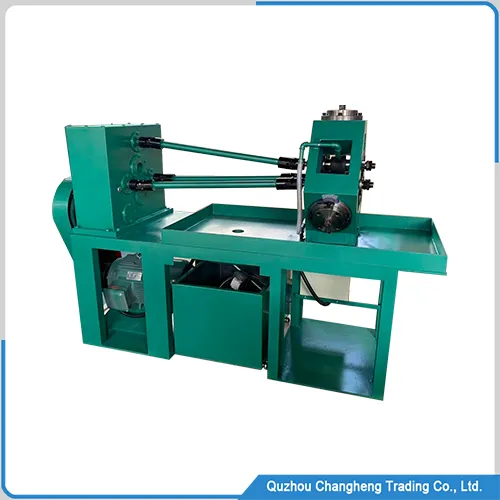

Fin roller machine

This machine consists of a feeder, roller mold, cutting device, lubrication device, control system, etc. Its production speed is 80 meters per minute, and the aluminum fins it produces are mainly use for car engine radiators and condensers,

This machine’s characteristic is its fast production speed. A servo motor controls the cutting device, and the length of each fin can maintain good consistency.

Fin press machine

This machine needs to be use in conjunction with fin molds, and its fastest production speed is 250-300 presses per minute. The fins it produces in household air conditioning condensers, refrigerated car evaporators, etc

The equipment is a complete production unit that includes a raw material feeder, lubricating oil tank, stamping machine, and fin storage device.

Fin tube machine

This machine squeezes fins onto pipes, which can be any metal. The material of the fins can only be aluminum or copper, and these pipes are widely use in cooling, petroleum, shipbuilding, and other industries.

This finning machine is driven by an 11kw motor, which drives the gear to output strong torque to drive the roller mold. The mold can squeeze metal pipes to form the shape of fins.

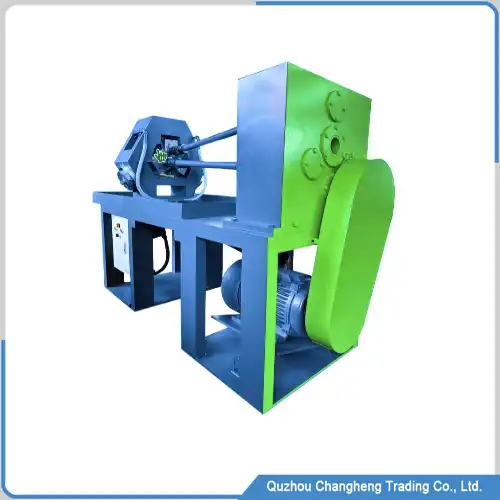

Fin making machine

This equipment is designed with four pillars, and the motor drives the cam to make the movable plate move the piston.

The four pillars are equipped with an automatic lubrication device

This machine can produce serrated, wavy, louvered, and staggered types of fins, which are essential for plate and bar-type heat exchangers,

Why choose our device

1, A strong team of engineers,

Our team has an average working age of over 15 years, and no matter what type of fin machine you need, our engineers can provide you with satisfactory service,

2, Highly competitive prices

We cooperate with excellent factories in China, entrusting third-party production of some simple parts to control costs and provide customers with competitive machines effectively

3, After-sales service

No matter where your factory is, we will send the machines to your factory. If necessary, our after-sales engineers will go to your factory to install the machines and train your engineers.

WECHAT

WECHAT