Fin mold supplier outline

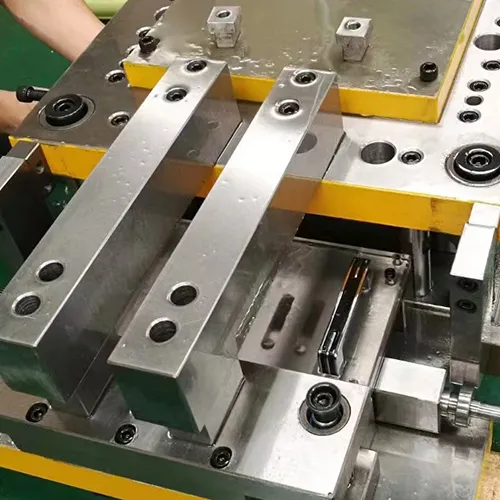

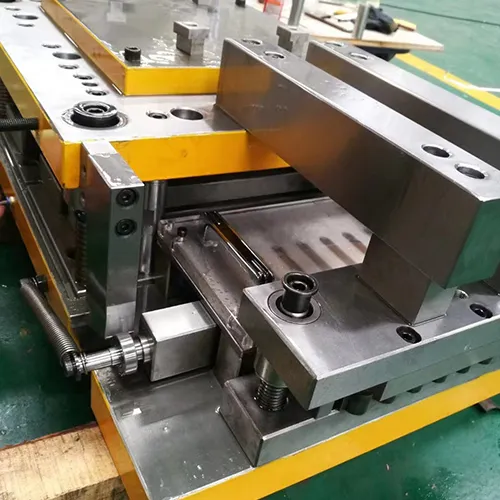

We are a top fin die supplier from China, and our engineers have an average working age of over 16 years. The mold factory has 5 CNC machines, 3 high-precision grinders, and several other machines. The entire factory covers an area of approximately 2000 square meters.

Our factory manufactures 80% of the parts for the stamping fin molds, which effectively manages the production schedule and is very helpful for on-time delivery.

Whether you need fin-pressing molds for HVAC, heat exchangers for the home heating industry, or inner fins for shell and tube heat exchangers, we can provide you with satisfactory solutions.

Raw materials of fin die

| No. | Prat Name | Data |

| 1 | Louver parts | SKH51 |

| 2 | Spring | 50CrVA |

| 3 | Punching needles | SKH51 |

| 4 | Small plates | Cr12MoV |

| 5 | Main plates | ENC45 |

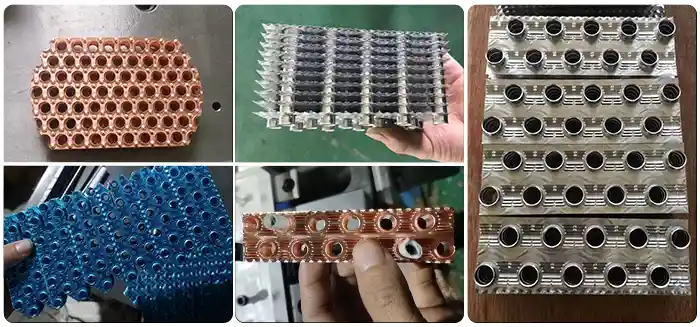

Types of molds

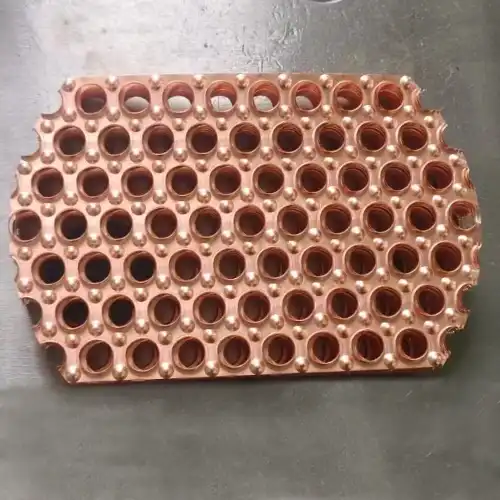

There are louvers around the holes of this fin, and the wind can blow through the louvers, taking away the heat from the heat exchanger and improving its cooling effect

The heat exchanger produced by this type of fin mold usually requires electric heating and features a high collar

Heat exchanger fin die Technical parameters

- Continuous production: Yes

- Hole array: 25.5*23mm

- Fin width: 180mm

- arrange: 12 rows

- Overall size: 1050*540*240mm

- Hole size: (3/8’’) 9.53mm

- Accept custom sizes: Yes

- Appearance color: default yellow

- Trimming shape: Wave

Heat exchanger fin die supplier factory video

Our advantages

1, We can customize fin molds according to customer requirements. No matter which field your fins are used in, we can provide excellent solutions

2, Innovative structural design, equipped with limit devices for the mold, ensures that any malfunctions in your stamping machine will not affect the fin mold

3, The key position of the mold is equipped with a lubricating oil device, which can be connected to the lubrication system of the stamping machine to achieve automatic lubrication

4, Because the parts of the stamping die are manufactured in our factory, our cost competitiveness is evident

FAQ

A: This fin die is packing in wooden cases

A: Our die delivery time is 50-62 days

A: We can customize this mold based on your stamping machine

WECHAT

WECHAT