Equipment Overview

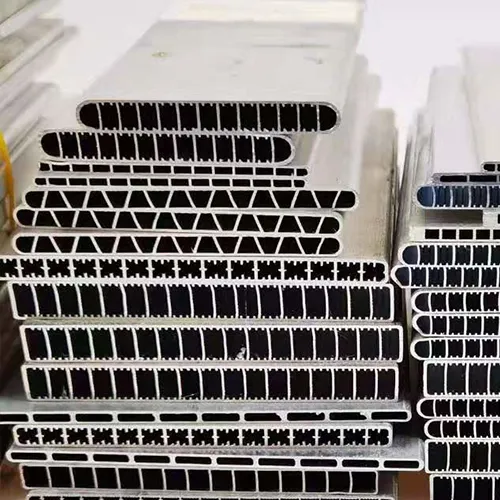

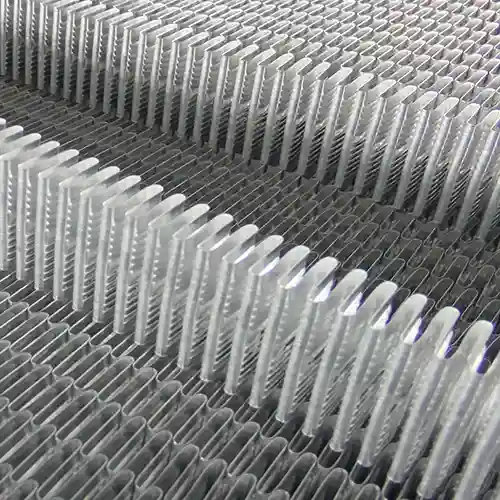

The intercooler core assembly machine is a device uses to produce intercoolers in trucks. Its main driving method is a servo motor, and the cylinder serves as an auxiliary drive.

This machine adopts a multi-scale application design, which means it can produce various sizes of truck intercoolers. This design is very friendly for intercooler factories producing aftermarket intercoolers.

The characteristics of the machine

- Simple structure:

A machine’s design does not have complex components, which means it is easy to assemble, use, and maintain while potentially reducing manufacturing costs.

- No noise:

Almost no noise is generated during operation, providing a more comfortable working environment for operators

- Energy saving:

The intercooler core assembly machine uses a servo motor drive to consume less electrical energy, which helps to reduce operating costs

- Adopting a human-machine interface:

The machine is equipped with a user-friendly operating interface, and changing different intercooler models only requires changing parameters through the touchscreen

Intercooler core assembly machine data

| No. | ITEM | DATA |

| 1 | Power supply: | 380v |

| 2 | Touch screen: | 10.1-inch |

| 3 | Max Core width: | 800mm |

| 4 | Max Core length: | 1000mm |

| 5 | Tube type: | Microchannel |

| 6 | Machine color: | Any color |

| 7 | Drive type: | servo motor pneumatic |

| 8 | Product: | Intercoolers radiators |

Intercooler core assembly machine working video

Why choose us

- A strong after-sales team,

Our engineers have an average of 15 years of work experience and can provide any aluminum brazing or other technical services for your factory.

- Highly competitive prices

Our machinery is industry-leading and has an excellent cost-performance ratio. Our advantages in the automotive and truck aluminum intercooler industry are undeniable.

- Transportation services

We serve our global customers, and no matter which country you are in, our intercooler core assembly machines can be deliver to your factory.

WECHAT

WECHAT