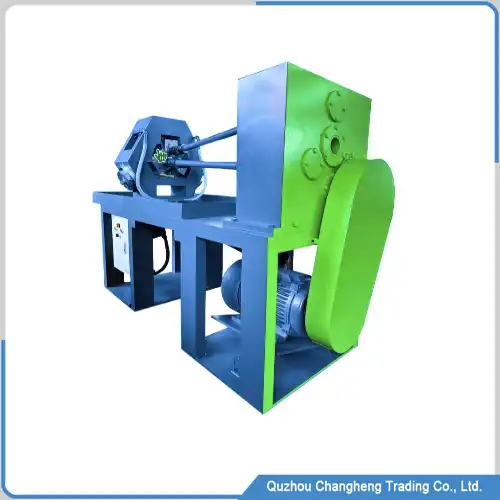

Machine Overview

The Copper fin tube machine is an efficient manufacturing equipment that can produce finned tubes of various metal materials, including carbon steel, stainless steel, copper, and various alloys.

These finned tubes can be either single metal materials or bimetallic finned tubes composed of two different metals.

In addition, the machine can also be used in conjunction with aluminum copper fin tubes of different diameters to meet different application requirements.

Technical Parameters

| No. | ITEM | DATA |

| 1 | Inside tube material | carbon steel stainless steel aluminum copper alloy |

| 2 | Fin material | copper aluminum |

| 3 | Fin thickness | 0.2-0.5mm |

| 4 | Fin height | <17mm |

| 5 | Outer diameter | Φ25-88mm |

| 6 | Fin pitch | 1.5-8mm |

| 7 | Max. length | < 20m |

| 8 | Overall dimension | 205*76*143cm |

| 9 | motor power | 11kw |

| 10 | Machine weight | About 1650kg |

Main features of copper fin tube machine

1, The rolling cutter mold adopts an advanced double arc key structure design, which can effectively withstand torque and maintain accuracy and reliability of displacement.

2, The blade of the roller mold adopts a split design, which makes the debugging of the blade very simple, and the blade can be easily cleaned and installed.

3, The main shaft bearings of the copper tube fin machine adopt tapered dynamic sliding bearings, which can maximize the utilization efficiency of the bearings.

4, The connection method of universal joints and shaft keys is used in all production lines to ensure the stability and efficiency of transmission.

5, The cooling box and rolling mill are designed separately, which helps optimize the cooling effect and improve production efficiency.

application area

The copper fin pipe machine is widely used in the following fields:

- Heat exchanger

- condenser

- radiator

- Heating industry

- Shipbuilding industry

- Oil Refinery

copper fin tube machine working video

FAQ

A: Yes, it can produce single metal fin tubes.

A: It will take about 2-3 hours.

A: A skilled engineer, takes approximately 1 hour to replace the mold.

A: The fastest delivery time for this machine is 25 days.

WECHAT

WECHAT