Machine Overview

In the automotive industry, the condenser tube production line has achieved a fully automated production process from aluminum foil to finished tubes.

Firstly, the aluminum foil material is precisely bent into a circular tube shape, and then the seams are firmly welded using high-frequency welding technology.

After welding is end, the machine automatically removes excess weld scars to ensure a smooth and flawless surface of the pipe. Finally, according to the predetermined length requirements,

the pipe is precisely cut. This series of operations is automatically completed by the machine, ensuring production efficiency and product quality.

Condenser tube production line data

Advantages of the production line

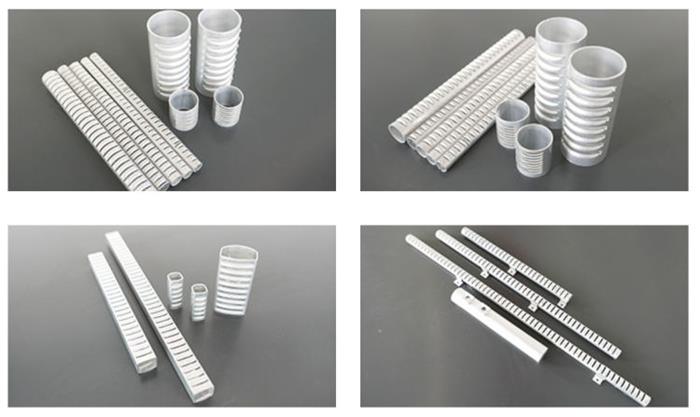

Modular design of molds

Modular structure molds can change quickly within a certain time, saving valuable time for production.

Visual settings

A 10-inch touchscreen allows engineers to operate and set various parameters of the machine visually,

Eliminate weld scars

This production line needs internal and external weld scar elimination devices, which operate automatically during the production process without worker supervision.

Automatic liquid cooling

The machine has a liquid cooling device and a fan, and the coolant is circulated for use without requiring frequent manual changes.

Condenser tube production line factory layout

The external dimensions of this production line consist of aluminum tube manufacturing machines, high-frequency welding machines, welding machine transformers, raw material feeding machines, aluminum tube cutting devices, coolant circulation devices, and other parts

The high-frequency welding machine and the variable pressure machine of the welding machine occupy a lot of space, so installing a complete condenser tube production line requires a factory area of approximately 15 meters in length and 5 meters in width

15 * 5 meters is the smallest machine installation location. Considering the transportation channels for raw materials and aluminum pipes, the actual factory requires more area

The installation of aluminum foil for coils requires a small crane and the minimum length of the factory workshop is 20-25 meters

FAQ

A: One mold produces the diameter of one tube, and you can change the mold to produce more sizes.

A: This is a precision machine, and the fastest delivery time is 120 days.

A: The thickness of the condenser tube exceeds 1.5mm, and its fastest production speed is 60-80 meters per minute.

WECHAT

WECHAT