Product Description

The coil tube expansion machine is a production equipment for industrial heat exchangers. It is the latest generation of equipment, which uses a servo motor as the main power, accurately controls the pushing length of the expanding rod, and realizes the uniform expansion of copper tubes.

This machine has eliminated the traditional hydraulic station and won’t produce any noise during operation. Therefore, more and more heat exchanger manufacturers are adopting this convenient type, servo-motor-driven Expansion machine as their primary production equipment in their factories.

Technical Parameters

- Expanding rod length: 6 -10 meters.

- Ball size: Customizable according to user’s needs.

- Expanding ball material: Tungsten steel.

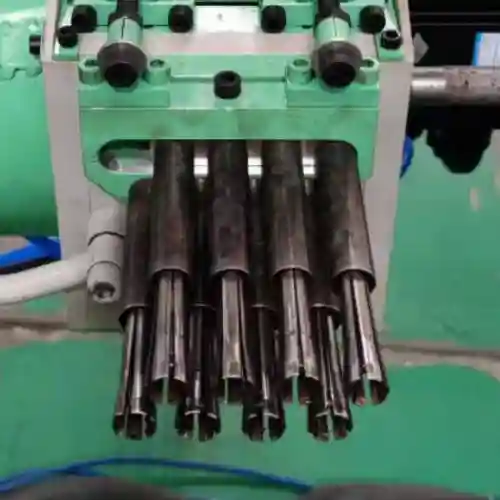

- Expanding rods: 2-8 optional.

- Servo motor: 2.2kw

- Servo motor brand: Delta.

- Tube materials: copper pipe, iron, aluminum, stainless steel, titanium alloy, etc.

- Tube geometric arrangement: Following the fin mold.

- Power supply: According to the standards of the user’s country.

- Touchscreen: 7 inches.

- Touchscreen language: English, Chinese, or other options available.

- Delivery time: About 45 days.

- Packaging material: Sterilized wood.

Coil tube expansion machine advantage

- Precisely control the length of the expanding rod’s advancement.

Due to the unique nature of servo motors, the required length can be accurately calculated through software algorithms. Engineers only need to set the required length through the touchscreen, and the machine can automatically control it.

- It is very energy-saving in production.

The manufacture of heat exchangers is generally an indirect process. Since servo motors stop consuming electricity when not in use, this Expansion machine saves 50% more electricity than other machines.

- There will be no noise at all at work.

The coil tube expansion machine is driven by a servo motor, which does not emit high-decibel noise like a hydraulic station. This machine has very little impact on the environment.

- It presets multiple intelligent controls.

The size and function of the heat exchanger produced by each factory are different. To meet the needs of all customers, this machine is equipped with various control methods, and it can switch between different production modes to achieve intelligent control.

Coil tube expansion machine Applications

The servo motor drives multiple sets of gearboxes to output a powerful torque, and the tube does not need to be lubricated. The coil tube expansion machine can easily expand copper, aluminum, stainless steel, titanium alloy, and other metals. Therefore, this machine is widely used and mainly has the following application scenarios.

1. The condenser and heat exchanger of a household air conditioner.

2. Large-sized industrial heat exchangers, usually the tube length of this product is 3-6 meters.

3. A tube-type heat exchanger, the tubes of which are usually made of stainless steel and titanium alloy.

4. The coil used in special environments is a heat exchanger; its fins and tubes are all made of stainless steel.

5. In the heating industry, the heat exchanger and heat exchanger tubes are usually oval, and our machine can easily handle them.

Coil tube expansion machine working video

Tube Expansion Machine advanced function

The key part of this pipe expansion machine is its replaceable design, allowing users to swap out different tools according to their production needs and enabling the production of multiple sizes.

This design effectively reduces users’ usage costs, and the application of multiple sizes can meet the diversified requirements of the market, thus opening up more business opportunities.

Give an example to illustrate this problem.

When you want to expand the diameter of the tube to 12.7mm, and now you want to change it to 15.88mm, then you only need to replace the expanding ball. The whole process only takes about 1-2 minutes.

When your tube spacing is 25.4mm, and you want to change it to 35mm, you only need to replace a simple tool. This process takes about 5-10 minutes.

When your expanding tube is 6, and you want to change it to 4 tubes, this process will take about 30-60 minutes.

Installation precautions

We provide a lot of tube expansion machines for heat exchanger factories all over the world. Users can easily install this machine according to our instructions.

Our manual is written according to the way beginners. It covers almost all the details, so you don’t need to worry about installing and using the machine.

Since the servo motor of this expanding machine uses absolute value control, the advantage of this control method is that no matter how many incorrect parameters you set, it can easily find the origin, and you just need to initialize the settings.

The only downside is that when you use this machine for the first time, you must set the parameters for the servo motor driver and follow our instructions strictly; otherwise, the machine won’t work correctly.

Final and summary

This coil tube expansion machine is a modern equipment, which adopts the advantages of servo motor drive and so on. It can meet the production of various industrial coil heat exchangers.

If you’re really looking for an Expansion machine that meets your production needs, then this machine might be your best choice.

You can contact our engineers to get the latest machine parameters and more details.

WECHAT

WECHAT