Product Description

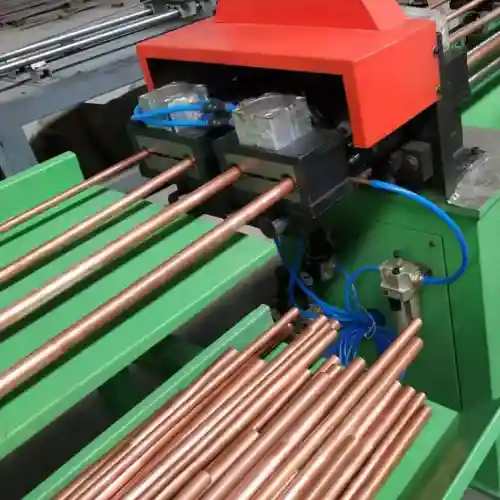

The HVAC industry uses an automatic copper Tube cutting machine, which consists of a copper pipe frame, straightening device, chip-free cutting, and other parts.

This device has multiple workstations, each of which can run independently and set different copper tube diameters to accommodate more heat exchangers.

Its straightening device is driven by a servo motor screw rod, which can set the length of any pipe and accurately control the consistency of each copper pipe.

Feature of copper tube cutting machine

- Highly automated

Almost no manual involvement is required throughout the entire production process; only the length and output of the pipes need to be set. It will automatically complete production and shut down.

- Exquisite appearance

The appearance of the device adopts spray painting technology, which conforms to the aesthetic of modern industry

- centralized control

The copper tube cutting machine has a touch screen, and engineers can set all parameters. This centralized control operation method is very convenient.

- Stable quality output

Multiple rollers straighten the pipes, and servo motors precisely control their length. Each pipe’s tolerance will not exceed 0.1mm.

- Shaftless cutting

The cutting device adopts advanced chip-free cutting technology, and the copper tube will not leave any burrs. This type of tube is very easy to insert into the fin hole.

Technical Parameters

- Tube materials: copper and aluminum

- Pipe diameter: 5-20mm

- Pipe wall thickness: 0.2-1mm

- machine type: Multiple workstations

- Production efficiency: 1 piece/5-8 seconds

- Air pressure: 0.4-0.6mpa

- Workbench height: 800mm

- Production mode: fully automatic

- Drive Type: servo motor and pneumatic

- Appearance color: default gray white

- Electricity consumption: 6.5kw/h

- Power supply: 380V three-phase

- Dimensions: 12 * 1.5 * 1.6 meters

Copper tube cutting machine working video

Copper tube cutting machine work steps

The production steps of this machine are as follows

Step 1

Install the coil tube on the rack, turn off the safety device to prevent it from falling, and install the coil quantity according to production needs.

Step 2

Insert the pipe into the channel of the straightening roller until the end, and manually control the clamping device to clamp the pipe.

Step 3

You can set the length and quantity of the tube through the touch screen, then manually run the equipment at low speed to check if it can produce smoothly.

Step 4

Automatically operate the pipe-cutting machine and inspect the surrounding environment to ensure safe production.

Other heat exchanger equipment

Installation precautions

1, The bottom of the copper Tube cutting machine is equipped with foot adjustment screws, which users can adjust according to the factory’s ground flatness. Try to place the machine steadily

2, To provide a buffer safety distance for the tube, a minimum distance of 2-3 meters should be reserved between the coil tube installation device and the machine.

3, After cutting, the material-receiving device should reserve sufficient space according to the user’s product size. If need 5-meter pipes, 5-6 meters of space should be reserved here.

4, Please note that this machine requires compressed air to function correctly.

WECHAT

WECHAT