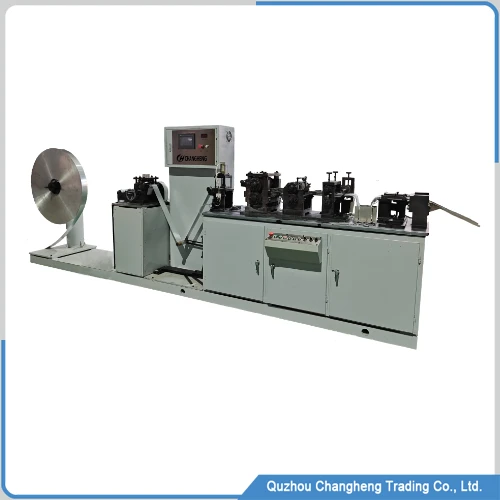

Machine Overview

The high-frequency welding aluminum tube making machine is an automated equipment for producing automotive radiator pipes. The main process flow includes: uncoiling, forming, high-frequency welding, cooling, sizing, straightening, cutting, and other steps.

Among them, high-frequency welding is the core process of the equipment, which uses high-frequency induction heating to weld the aluminum foil material into a flat tube, forming a weld seam.

After the welding seam is formed, it is automatically cut according to the length requirements, ultimately producing various specifications of automotive radiator flat pipes.

This aluminum tube making machine adopts automated production, which can greatly improve production efficiency and product quality.

At the same time, due to the use of high-frequency induction heating welding, the quality of the weld seam is high and leakage is not easy to occur. In addition, the device also has advantages such as simple operation and high-speed production.

Therefore, the high-frequency welding aluminum pipe-making machine has been widely used in the production of automotive radiator pipes.

Aluminum tube making machine main parameter

| No. | ITEM | DATA |

| 1 | Production speed | max. 120m/min |

| 2 | Cooling mode | PLC + touchscreen |

| 3 | Control system | PLC + touch screen |

| 4 | Foil materials | 4343 / 3003/ 7072 3003 |

| 5 | Installed capacity | 168kva |

| 6 | Overall size | 30*5*3.5 m |

| 7 | Forming method | flat tube direct forming flat tube welding flat tube sizing |

| 8 | Cutting frequency | max 200 pieces/min |

| 9 | Gross weight | about 18 tons |

Production steps

Step 1: Aluminum foil feeding

The raw material unwinding device of the aluminum tube making machine smoothly delivers the aluminum foil to the forming position, which is a crucial step in the entire production process.

Step 2: Preliminary molding

After preliminary molding, the aluminum foil has become an olive-shaped aluminum tube.

Step 3: High frequency welding

A high-frequency welding machine welded the aluminum tube together on both sides to form a closed aluminum tube.

Step 4: Cooling treatment

The welded aluminum pipes are cooled using a cooling device to ensure the strength and stability of the welded joints.

This step is also one of the important steps in the aluminum tube making machine.

Step 5: Forming aluminum tubes

Here are multiple sets of rollers that accurately shape the flat tubes’ final dimensions, ensuring the aluminum tubes’ consistency.

Step 6: Cutting

This is the final step of the aluminum tube manufacturing machine, cutting each tube according to the set length.

WECHAT

WECHAT