Overview

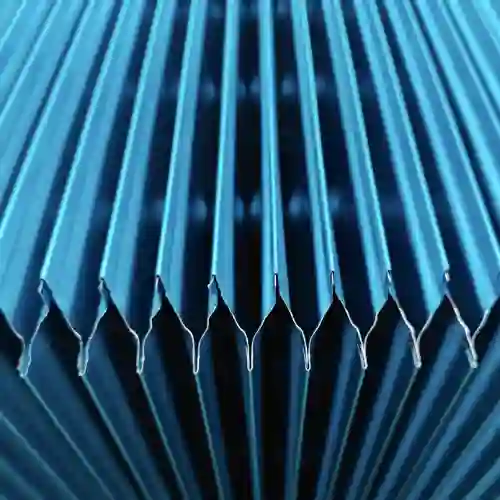

The characteristic of an air to air heat exchanger is that it is composed of multiple aluminum plates stacked together. After sealing on both sides, one side enters hot air and the other side enters cold air. They exchange heat through their respective channels

The plate material of this type of heat exchanger is usually aluminum, which needs to be used in some special environments. Stainless steel material has better corrosion resistance. With the development of industry, some fields also use plastic fibers, which have lower costs. However, currently, the mainstream is still aluminum material, which has the best heat exchanger efficiency

How to produce air to air heat exchanger

Some European factories, use traditional stamping machines to produce air-to-air core plates, and each size requires a mold, which is a costly solution

When replacing the mold of the punching machine, engineers need a lot of time to adjust the working program of the robotic arm, which is very unfavorable for large-scale production

Nowadays, factories in China have a professionally designed production line for this heat exchanger plate type. It not only perfectly solves these shortcomings but also improves production efficiency. Please check this video for more information

technical parameter

| No. | ITEM | DATA |

| 1 | Maximum size | 120 * 120CM |

| 2 | Minimum size | 20 * 20cm |

| 3 | Press type | 4-column hydraulic |

| 4 | Plate material | aluminum stainless steel |

| 5 | Plate spacing | 5-14mm adjustable |

| 6 | Hydraulic station | servo drive (optional) |

| 7 | Control mode | touch screen |

| 8 | PLC brand | Siemens |

| 9 | Production type | fully automatic |

air to air heat exchanger Advantages of production line

1, Producing aluminum plates of various sizes without the need to replace molds, which not only saves investment costs but also significantly improves production efficiency

2, This machine is specifically designed for the production of heat exchangers. Compared to traditional stamping machines, it has significant absolute advantages in terms of cost-effectiveness and production efficiency

3, Fully automated production of aluminum plates, without the need for workers to supervise the entire production process, and without wasting any raw materials

4, The air-to-air heat exchanger production line adopts a four-column hydraulic design to press each aluminum plate smoothly, effectively ensuring product consistency

5, Each edge of the aluminum core has 2 bends, which does not require the addition of glue and there is no risk of leakage

air-to-air heat exchanger application

With the increasing awareness of environmental protection and the reduction of energy waste, Their application is very extensive in these fields,

- Supermarkets

- Office Building

- Computer room

- Residential buildings equipped with central air conditioning

- hospital

- government office building

WECHAT

WECHAT